Industrial turnarounds are short-term events with high-stakes consequences. Though they may only last a few days or weeks, they account for some of the most hazardous working conditions in the industrial sector.

A study published in Chemical Engineering Progress states that over 50% of all major plant accidents occur during maintenance shutdowns or turnarounds, not during normal operations.

A turnaround is a planned shutdown in facilities like refineries, chemical plants, or manufacturing units to perform maintenance, upgrades, or inspections. These periods involve high-risk tasks such as hot work, confined space entry, lifting operations, and hazardous material handling, often happening simultaneously, in close quarters, and with contractors unfamiliar with the site.

That’s precisely why you need a Turnaround Safety Specialist (TSS). These experts are your frontline defense against accidents, delays, and compliance failures. From planning through execution, they keep your people safe, your project on track, and your facility protected.

This blog will explore who Turnaround Safety Specialists are, what they do, and why your facility can’t afford to run a turnaround without them.

Turnaround Safety Specialists: Who They Are and Why They Matter

A Turnaround Safety Specialist is a trained safety professional responsible for ensuring that all safety procedures and regulations are followed during industrial turnarounds, which are planned shutdowns of plants for maintenance, inspections, or upgrades. These specialists help prevent accidents, injuries, and regulatory violations during high-risk operations.

Core Functions

Turnaround Safety Specialists identify hazards before and during the turnaround and ensure that safety measures are implemented and followed. They monitor the worksite to prevent unsafe behavior or conditions and ensure everyone, including contractors, understands and follows safety procedures. They act as the link between safety regulations and daily operations during the turnaround period.

Background and Experience

Most Turnaround Safety Specialists come from fields related to occupational Health and Safety (OHS), industrial Hygiene, Environmental Health and Safety (EHS), and safety engineering.

They often have hands-on experience in oil and gas, petrochemicals, power generation, and manufacturing. Their experience helps them understand site-specific risks and how to manage them under strict timelines and heavy workloads.

Certifications and Training

The Certified Safety Professional (CSP) credential is a key certification covering advanced safety principles and risk management. Many specialists also complete OSHA training to ensure compliance with U.S. safety regulations.

The NEBOSH certification is highly respected for international work, providing expertise in global health and safety laws. Those handling hazardous materials often hold HAZWOPER certification, focusing on emergency response and PPE use. First Aid/CPR and Confined Space Entry training prepare specialists for emergencies and confined work environments during turnarounds. Together, these certifications ensure a safe and compliant workplace during high-risk shutdowns.

| Certification | Offered By | Focus Areas |

| Certified Safety Professional (CSP) | Board of Certified Safety Professionals (BCSP) | Advanced safety principles, risk assessment techniques, and safety program management |

| OSHA Training | Occupational Safety and Health Administration | Identifying workplace hazards, implementing safety controls, and ensuring U.S. regulatory compliance |

| NEBOSH | National Examination Board in Occupational Safety and Health | Global health & safety laws, risk management strategies, and incident investigation |

| HAZWOPER | OSHA (U.S.) | Emergency response readiness, PPE use, hazardous waste operations, and decontamination procedures |

Turnaround Safety Specialists: Why Their Expertise Saves Lives and Time

Turnaround Safety Specialists are essential because industrial turnarounds involve increased risks, tight deadlines, and legal requirements. Without dedicated safety professionals, the chances of accidents, delays, or regulatory violations increase significantly. Here are a few reasons why they are essential:

1. High-Risk Environment

During a turnaround, routine operations stop and are replaced by maintenance, cleaning, equipment replacement, and upgrades. These tasks often introduce hazardous conditions:

- Hot Work: Activities like welding or cutting can cause fires or explosions if flammable gases or materials are present.

- Confined Space Entry: Tanks, vessels, or pits have limited entry and exit points, low oxygen levels, and toxic gas risks.

- Working at Heights: Scaffolding, ladders, and overhead equipment create fall risks.

- Chemical Exposure: Handling or cleaning equipment may expose workers to hazardous substances.

For example, a contractor may need to clean a storage tank during a refinery shutdown. They could be exposed to highly toxic hydrogen sulfide without proper gas testing. A Turnaround Safety Specialist ensures gas monitoring and adequate ventilation before entry.

Turnarounds often involve outside contractors unfamiliar with the facility’s layout, equipment, or safety culture. This increases the risk of errors and miscommunication. The Safety Specialist ensures they are adequately briefed and monitored.

2. Compressed Timelines

Turnarounds are costly. Every hour the plant is down means lost production. This creates pressure to complete tasks quickly, leading to workers skipping safety steps. Supervisors push teams to meet deadlines over protocols, and fatigue from extended shifts leads to poor decision-making.

The turnaround safety specialist ensures safety procedures are followed under time pressure and identifies when tasks should be paused due to unsafe conditions.

For instance, a team is behind schedule on replacing a valve and decides to bypass Lockout/Tagout procedures to save time. In that case, a Turnaround Safety Specialist can stop the task until it’s done safely, preventing electrocution or mechanical injury.

3. Compliance and Legal Requirements

Strict health and safety standards govern industries such as oil & gas, chemicals, and manufacturing. In the U.S., regulatory bodies include OSHA (Occupational Safety and Health Administration), which sets workplace safety standards; the EPA (Environmental Protection Agency), responsible for environmental protection and chemical handling.

Non-compliance with these regulations can lead to serious consequences, including heavy fines and citations, shutdowns or delays due to failed inspections, legal liabilities in the event of injuries or fatalities, and damage to a company’s reputation and insurance standing.

Turnaround Safety Specialists are crucial in mitigating these risks by ensuring site operations comply with all required safety standards, maintaining proper documentation for audits and regulatory visits, and conducting daily inspections to identify and correct unsafe practices.

Essential Responsibilities of a Turnaround Safety Specialist

Turnaround Safety Specialists are responsible for planning, managing, and enforcing safety procedures before, during, and after a plant shutdown. Their work is divided into these essential phases:

1. Pre-Turnaround Planning

Risk Assessments (JSA, HAZOP, SWMS)

Before work begins, the Safety Specialist conducts Job Safety Analyses (JSA), Hazard and Operability Studies (HAZOP), and Safe Work Method Statements (SWMS). These tools help identify specific hazards associated with each task, evaluate potential risks, and define control measures to reduce the chances of accidents.

Developing the Turnaround Safety Plan

This document outlines all safety procedures for the shutdown. It includes hazard control strategies, permit requirements, roles and responsibilities, and emergency contact lists. The plan is reviewed with stakeholders before execution begins.

Planning Safety Logistics

Logistics include setting up evacuation routes, emergency muster points, first-aid stations, and ensuring personal protective equipment (PPE) is available and accessible. These preparations are necessary for quick responses during emergencies.

2. Training and Briefings

Toolbox Talks and Safety Inductions

Safety Specialists lead daily toolbox talks highlighting risks and procedures for that day’s tasks. Before the turnaround, all workers undergo safety inductions to understand site rules and emergency procedures.

Ensuring Protocol Awareness Across Teams

The specialist ensures plant employees and external contractors understand how to work safely on site. They verify that everyone has received the required training and signed off on safety documentation.

Considering Language, Literacy, and Culture

Because many turnaround sites employ a diverse workforce, safety instructions are adjusted to overcome language barriers or literacy challenges. Visual aids and translators may be used to ensure clarity and understanding.

3. Active Monitoring During Turnaround

Site Audits, Safety Walks, and Spot Checks

Turnaround Safety Specialists perform frequent walkthroughs to check for unsafe behaviors, blocked access points, or improper PPE usage. They document findings and take corrective actions immediately.

Procedure Enforcement (LOTO, Confined Space, Hot Work)

They enforce critical safety procedures such as:

- Lockout/Tagout (LOTO): Isolating energy sources before maintenance.

- Confined Space Entry: Ensuring permits, gas testing, and standby personnel.

- Hot Work: Monitoring permits, fire blankets, and fire watch during welding or grinding.

Incident and Near-Miss Management

If an accident or near-miss occurs, the specialist secures the scene, investigates the cause, and documents the findings. This helps prevent similar incidents from happening again.

4. Emergency Preparedness

Setting Up Emergency Protocols

The Safety Specialist establishes clear procedures for medical emergencies, chemical spills, fires, and evacuations. This includes visible signage, trained personnel, and equipment like eye-wash stations and fire extinguishers.

Fire Watch, Spill Control, and Rescue Plans

A fire watch is assigned during high-risk jobs. Spill control kits are placed at critical locations. Rescue plans are developed, especially for confined space work, detailing how to remove injured or unconscious workers quickly.

Coordination with Emergency Services

The specialist works closely with EMTs, fire departments, or on-site rescue teams to ensure that all parties know their roles and can respond quickly to an incident.

5. Real-Time Communication and Reporting

Using Radios, Software, or Mobile Tools

Communication is maintained via radios, mobile apps, or safety platforms that allow instant issue reporting and coordination. This reduces response delays and increases accountability.

Coordination with Supervisors and Managers

Safety Specialists regularly contact turnaround coordinators, supervisors, and HSE managers to report concerns, approve permits, and escalate issues when needed.

Documentation for Audits and Compliance

Every inspection, briefing, and incident is documented. These records are used for internal audits, insurance claims, regulatory compliance checks, post-turnaround reviews, and lessons learned.

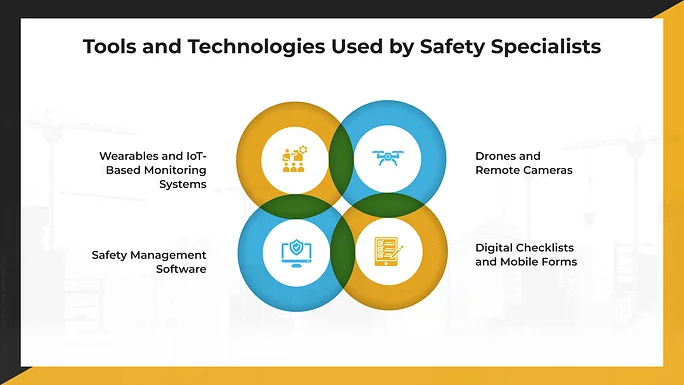

Tools and Technologies Used by Safety Specialists

Turnaround Safety Specialists use various tools and technologies to improve safety monitoring, speed up reporting, and reduce human error. These solutions help make shutdowns more efficient and compliant with safety standards.

1. Wearables and IoT-Based Monitoring Systems

Wearable safety devices and Internet of Things (IoT) technology help track worker health and environmental conditions in real time.

- Gas Detection Sensors: These devices detect dangerous gases like hydrogen sulfide or carbon monoxide, alerting workers before their levels become hazardous.

- Fatigue Monitoring Wearables: These track movement patterns and signs of exhaustion, helping identify workers at risk of accidents due to tiredness.

- Fall Detection Devices: Sensors trigger alerts if a worker falls, enabling a fast emergency response, especially in isolated or high-risk areas.

These tools reduce response time in emergencies and help prevent serious incidents before they happen.

2. Safety Management Software

Digital safety platforms allow specialists to manage documentation, inspections, training, and compliance tasks in one place.

- EHS Insight: Used for tracking incidents, scheduling audits, and managing safety training records.

- SpheraCloud: Helps manage risk assessments, corrective actions, and regulatory compliance across multiple teams.

These tools reduce manual paperwork, improve data accuracy, and ensure no key safety step is missed during a turnaround.

3. Drones and Remote Cameras

Visual inspection tools allow safety specialists to monitor hard-to-reach or hazardous areas without sending personnel into risky zones. Drones are used to inspect tall structures, pipelines, or large tanks, capturing live video or images from above.

Fixed Cameras are installed in confined spaces or remote areas to provide a live feed for safety monitoring without requiring a physical presence. These tools help reduce human risk exposure while maintaining complete site visibility.

4. Digital Checklists and Mobile Forms

Digital forms are used to conduct safety inspections, permit tracking, and task-specific safety checks directly from mobile devices.

Mobile safety checklists are used during daily walkthroughs to record observations and flag issues immediately. Permit-to-Work Forms are filled and signed digitally to save time and ensure records are stored securely. This simplifies data collection, reduces paperwork errors, and speeds up decision-making during critical operations.

What Challenges Safety Specialists Face During Turnarounds?

Despite best efforts, they face several practical challenges that can affect the effectiveness of safety programs. Here are a few of these challenges:

1. Resistance from Workers and Contractors

Due to strict deadlines, some workers and contractors may resist following safety procedures. They might see safety protocols as time-consuming or unnecessary, especially when trying to meet targets.

This resistance can lead to unsafe behavior, such as bypassing Lockout/Tagout steps or entering confined spaces without proper checks. Safety specialists must enforce rules consistently, even when facing pushback.

2. Fatigue Management

Turnaround work often involves long shifts, night work, and consecutive days without proper rest. Fatigue increases the risk of human error, injuries, and slower response to hazards.

Safety specialists must monitor signs of exhaustion, adjust shift schedules if needed, and promote adequate breaks, even when production teams are pressured to speed up.

3. Inconsistent Safety Culture Across Contractors

Turnarounds usually involve multiple contractors from different companies. Each may have safety standards, training levels, and attitudes toward compliance.

This inconsistency makes it harder to apply a unified safety approach. Safety specialists must conduct joint briefings, verify contractor certifications, and ensure that everyone follows the same site-specific safety rules.

4. Changing Hazards in a Fast-Paced Environment

The nature of turnaround work is dynamic; tasks, personnel, and equipment change rapidly. A safe area in the morning can become hazardous by afternoon. Safety specialists must constantly reassess risks, update controls, and remain flexible in adapting safety measures. Delayed adjustments can result in incidents if new hazards are not identified in time.

Why Does Your Organization Need Turnaround Safety Specialists?

Hiring a Turnaround Safety Specialist helps protect your people, keep your project on track, and avoid costly mistakes. Here’s what you gain:

1. Reduce Injuries and Fatalities

Turnarounds involve high-risk work, hot surfaces, chemical exposure, and working at heights. A TSS is trained to spot danger before it becomes a serious problem. Their presence means fewer accidents, fewer medical emergencies, and fewer workers sent home injured.

2. Avoid Delays Caused by Safety Incidents

The work stops whenever there’s an injury, an equipment issue, or an unsafe condition. Investigations begin. Delays pile up. A TSS keeps operations safe and smooth by preventing these disruptions before they start, keeping your timeline intact.

3. Better Contractor Oversight

Most turnarounds involve outside contractors, who don’t always know your facility, rules, or safety expectations. A TSS ensures everyone, internal or external, follows the same standards, receives proper training, and is held accountable for safety violations.

4. Build a Strong Compliance Record

You’ll be ready when OSHA or your local authority inspectors show up. TSS professionals document everything, keep your records clean, and ensure you follow the law. This protects your plant from fines, shutdowns, and adverse reports.

Partner With Safe T Professionals For Trusted Staffing And Consulting Solutions

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s HSE protocols, ensure compliance with industry regulations, and mitigate workplace hazards. Whether you are looking to fill safety-specific roles or need expert consultation to reduce workplace hazards, we are here to help.

Connect with us today!