A near miss is an unplanned event that could have caused injury, damage, or loss but did not. It is often called a close call, a situation where something almost went wrong but was avoided by chance or quick reaction.

For example, a worker on a scaffold loses their balance but grabs a railing just in time. They avoid falling, but the unstable platform remains a hazard that could cause a serious accident.

Near misses are early warning signs of safety risks. Ignoring them increases the chance of real accidents in the future. Reporting and investigating near misses help workplaces spot hidden hazards before they cause harm. This allows them to improve safety procedures and prevent future incidents.

Treating near misses seriously helps businesses build a proactive safety culture. Instead of waiting for accidents, workplaces can learn from these close calls and make necessary improvements. This blog will explore the importance of near misses in workplace safety, how to recognize and report them effectively, and the steps organizations can take to investigate and prevent future incidents.

Understanding a Near Miss in Safety

The Occupational Safety and Health Administration (OSHA) defines a near miss as an unplanned event that did not result in injury, illness, or damage but had the potential to do so. These incidents are called close calls or narrow escapes.

For example, a worker on a scaffold loses their balance but grabs a railing just in time. They avoid falling, but the unstable platform remains a hazard that could cause a serious accident. No one got hurt, but if the conditions remained the same, a future incident could cause real harm.

Near Miss vs. Accident: What’s the Difference?

| Aspect | Near Miss | Accident |

| Outcome | No injury or damage | Results in injury, damage, or loss |

| Potential Risk | High – could lead to an accident in the future | Risk has materialized, causing harm |

| Example | A heavy object falls but narrowly misses a worker | A heavy object falls and injures a worker |

Common Causes of Near Misses in the Workplace

Near misses happen for various reasons, but most can be prevented with the right precautions. Here are some of the most common causes:

Lack of Proper Training or Awareness

When employees are not adequately trained, they may not recognize hazards or know how to avoid them. This lack of awareness increases the chances of near misses and, eventually, accidents.

For example, a new worker may operate heavy machinery without understanding safety procedures. Due to improper handling, they may nearly collide with another worker. Conduct regular safety training. Provide clear instructions for new employees. Use visual safety signs and reminders.

Unsafe Behavior or Negligence

Some near misses happen because employees take shortcuts or ignore safety rules intentionally or unintentionally; risky behavior puts everyone in danger. For example, a worker rushes down the stairs without using the handrail and nearly falls.

Encourage employees to follow safety rules at all times. Create a workplace culture that prioritizes safety over speed. Implement consequences for repeated unsafe behavior.

Equipment Failure or Improper Maintenance

Machines, tools, and equipment need regular maintenance to work safely. When they fail unexpectedly, they can cause near misses or accidents. For example, a forklift’s brakes fail, and the driver narrowly avoids hitting a stack of materials.

Schedule routine maintenance for all equipment. Train workers to inspect tools before use. Replace or repair faulty equipment immediately.

Poor Workplace Conditions

Unsafe environments create hazards that increase the likelihood of near misses. Common issues include slippery floors, poor lighting, and cluttered spaces. For example, a worker nearly trips over an extension cord stretched across a hallway.

Keep walkways clear of obstructions. Ensure proper lighting in all work areas. Regularly inspect and maintain floors, stairs, and workspaces.

Communication Gaps Among Employees and Management

Miscommunication or a lack of communication can lead to near misses. Employees may unknowingly put themselves in danger when safety concerns are not shared. For example, a maintenance team does not inform workers that an overhead pipe is leaking. A worker almost slips on the water but catches themselves in time.

Encourage open communication about safety concerns. Implement a near-miss reporting system.

Hold regular safety meetings to discuss potential hazards.

Best Practices For Building a Strong Near Miss Reporting Culture

A strong safety culture encourages employees to report near misses without fear. If employees hesitate to report, valuable learning opportunities are lost. Organizations must create an environment where reporting is regular and encouraged.

Overcoming Fear of Reporting

Some employees hesitate to report near misses because they fear blame, punishment, or judgment from coworkers, worrying they will be seen as careless or responsible. Others avoid reporting because they believe management won’t take action, making the effort seem pointless.

To overcome this, workplaces should ensure near-miss reporting is non-punitive, assuring employees they won’t face penalties. Communicating that near misses are learning opportunities, not failures, helps shift the mindset toward proactive safety. Allowing anonymous reporting can further reduce fear, and visibly acting on reports shows employees that their concerns lead to real improvements.

Encouraging Open Communication Between Workers and Management

Employees must feel comfortable discussing safety concerns for a reporting culture to work. Many workplaces struggle with communication gaps between frontline workers and management.

Regular safety meetings should be held where employees can freely discuss hazards. Supervisors should lead by example, reporting near misses themselves. Use two-way feedback: Employees report near misses, and management provides updates on corrective actions. For instance, a construction company can set up a monthly safety forum where workers openly share safety concerns and near-miss reports. Management listens and implements improvements.

Rewarding Employees for Reporting Near Misses

Incentives can motivate employees to participate in safety reporting. However, rewards should not be based on the number of reports (to avoid false reports) but on participation and improvement. Your organization can follow the below methods to reward employees:

- Recognition programs – feature employees in safety meetings or newsletters.

- Small incentives – gift cards, extra break time, or safety-related prizes.

- Team-based rewards – reward teams for achieving safety goals rather than individuals.

Managers and supervisors play a crucial role in shaping workplace safety culture. If leadership ignores safety concerns, employees may stop reporting near misses. To encourage a strong safety culture, leaders should actively participate in safety programs, take action on reports, and ensure concerns lead to real improvements. Encouraging continuous learning through regular training helps reinforce safety awareness. Most importantly, leaders must lead by example, following safety protocols and reporting near misses.

For instance, if a factory manager sees an employee almost trip over an extension cord, they should report it as a near miss and ensure it gets fixed. This proactive approach sets a strong example, reinforcing the importance of workplace safety.

SafeT offers a team of fully trained safety professionals ready to ensure your project’s success. Contact us to learn more!

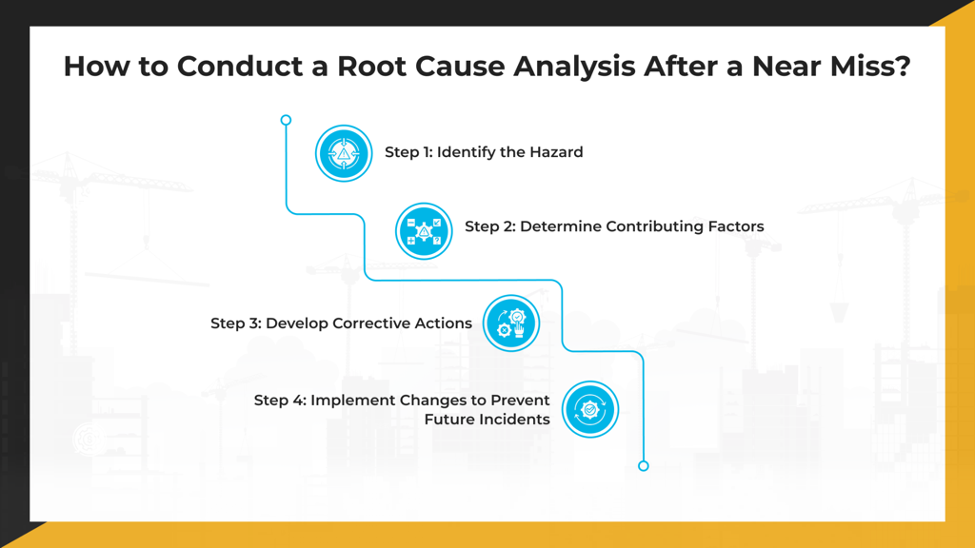

How to Conduct a Root Cause Analysis After a Near Miss?

A root cause analysis (RCA) identifies the underlying cause of a near miss instead of just treating the surface issue. It answers why the incident happened. Here is a list of essential questions to analyze before an incident occurs.

- What exactly happened?

- Where and when did it happen?

- Who was involved or affected?

- What were the conditions at the time?

- Why did the near miss occur?

Steps in a Near Miss Investigation

A step-by-step approach ensures the investigation is thorough and effective.

Step 1: Identify the Hazard

Determine what hazard caused the near miss (e.g., slippery floor, faulty equipment, miscommunication). Look for patterns – has this near miss happened before? For example, a worker almost gets hit by a forklift. The hazard? Forklifts operating too close to pedestrians.

Step 2: Determine Contributing Factors

Several factors often contribute to a near miss. These can include:

- Human error – Was the worker adequately trained?

- Environmental issues – Was there poor visibility or clutter?

- Equipment failure – Was maintenance skipped?

- Communication breakdown – Was there a lack of warning signals?

For instance, the forklift incident occurred due to multiple safety hazards. The designated pedestrian walkway was unclear, making it difficult for workers to navigate safely. The forklift’s warning alarm malfunctioned, preventing others from being alerted to its movement. Poor lighting further contributed to the issue, as the driver could not see the worker in time, increasing the risk of a serious accident.

Step 3: Develop Corrective Actions

After identifying the cause, the next step is fixing the problem to prevent future incidents.

Improve training programs for workers. Change workplace layouts to separate pedestrians from forklifts. Upgrade equipment maintenance schedules.

Several corrective actions should be taken to address the forklift incident. Painting clear pedestrian walkways will help separate foot traffic from forklift paths, reducing the risk of collisions. Installing brighter lights in the work area will improve visibility, ensuring drivers and pedestrians can see clearly. Additionally, it is crucial to ensure forklifts have functioning alarms, allowing workers to hear approaching vehicles and stay out of harm’s way.

Step 4: Implement Changes to Prevent Future Incidents

Once solutions are identified, companies must follow through and make sure they work.

Assign responsibility to determine who will ensure the fix happens. Set deadlines for completion. Monitor the effectiveness of the change. For example, if new walkway markings are added, supervisors should check in after a month to ensure they are used correctly.

Essential Tips For Preventing Near Misses and Improving Workplace Safety

Below is a list of essential strategies your organization must follow to prevent near-miss incidents.

Conduct Regular Safety Training and Awareness Programs

Employees need continuous training to recognize hazards and respond appropriately. One-time training is not enough, safety awareness should be conducted regularly.

Conduct safety workshops and refresher courses. Use real-life case studies of near misses to teach lessons. Provide hands-on emergency response drills for high-risk situations.

Conduct Routine Safety Audits and Risk Assessments

Regular safety audits help identify hazards before they cause accidents. Risk assessments evaluate the likelihood of an incident and its potential consequences.

Inspect work areas, equipment, and procedures for safety compliance. Identify high-risk tasks that require additional controls. Involve employees in hazard detection and improvement discussions.

Implement Engineering Controls to Eliminate Hazards

Engineering controls are physical changes to the workplace that reduce risks. Unlike training or policies, these controls remove hazards at the source.

Implementing safety measures can significantly reduce workplace hazards. Installing machine guards helps prevent accidental contact with moving parts, reducing the risk of injuries. Using ventilation systems improves air quality and minimizes exposure to harmful substances, creating a safer work environment. Additionally, replacing manual lifting with mechanical lifting devices reduces physical strain on workers, preventing musculoskeletal injuries and improving overall workplace safety.

Encourage Employee Participation in Safety Programs

Employees are the first to notice hazards, so their involvement is crucial. A strong safety culture encourages workers to speak up and take ownership of workplace safety.

Create anonymous reporting systems for safety concerns. Recognize and reward employees for suggesting safety improvements. Form safety committees with worker representatives to discuss safety measures.

Use Technology to Enhance Safety Monitoring

Advancements in technology (AI, IoT, Wearables) can significantly improve workplace safety by detecting risks in real time and preventing incidents before they happen.

Various safety technologies can help prevent workplace hazards. AI-powered analytics use past incident data to predict potential risks, allowing proactive measures. IoT sensors detect equipment malfunctions and environmental hazards in real time, ensuring quick response. Wearable devices monitor worker fatigue and exposure to harmful conditions, helping to prevent accidents and health issues.

Enhance Your Workplace Safety with Safe T Professionals!

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s safety protocols and ensure compliance with industry standards. Whether you are looking to fill safety-specific roles or need expert consultation to mitigate workplace hazards, we are here to help.

Connect with us today!