Incidents don’t give warnings, but risk management does.

A single equipment failure, safety lapse, or data breach can interrupt operations, delay projects, and inflate costs, sometimes within minutes.

According to Liberty Mutual’s Workplace Safety Index, U.S. businesses lose over $1 billion weekly due to preventable workplace injuries and disruptions. These figures reflect a deeper issue: many organizations react to incidents only after damage has been done, rather than preparing to prevent them.

This is where incident prevention and risk management come in, not as reactive measures, but as forward-looking strategies designed to anticipate and reduce harm before it occurs. Whether managing a manufacturing plant, a logistics network, or a corporate office, identifying and controlling risk is essential to maintaining safety, continuity, and performance.

Before looking into tools and techniques, it’s important to understand two foundational concepts. An incident is any unplanned event that disrupts normal operations, such as a machinery malfunction, a chemical spill, or a cybersecurity breach. A risk is the potential for such an event to occur, often assessed by its likelihood and severity.

This blog will explore how a structured incident prevention and risk management method can reduce losses, improve safety outcomes, and support business growth, regardless of industry.

Where Incidents Begin: Identifying the Causes of Unsafe Events

Incidents usually result from a combination of factors. Identifying these root causes is essential for preventing future risks. Below are the most common contributors:

1. Human Error

Errors can take many forms—misjudgments, lapses in attention, or incorrect actions- often driven by fatigue, stress, distraction, or inexperience. Even minor missteps can have serious consequences in high-risk environments like construction sites.

For example, operating machinery without proper focus or bypassing safety steps to save time can quickly lead to injury or equipment damage.

2. Inadequate Training

When employees are not thoroughly trained to use tools, follow safety protocols, or recognize hazards, they are more likely to make dangerous mistakes. This issue becomes more pronounced when new equipment is introduced or workers are assigned unfamiliar tasks.

3. Equipment Malfunction and Misuse

Machines used beyond their intended capacity or neglected in routine maintenance can become safety hazards. For example, failure to service lifting equipment or power tools in construction can lead to breakdowns, project delays, or even physical harm. Misuse, such as using the wrong tool for the task, increases the risk of mechanical failure.

4. Systemic and Organizational Failures

Poor communication, weak safety leadership, unclear responsibilities, and a lack of accountability often contribute to a culture where hazards go unreported or ignored.

For instance, if incident reports are discouraged or safety concerns are not addressed promptly, it creates a gap between what should happen and what happens on-site. A weak safety culture makes it easier for minor oversights to compound into larger, more dangerous incidents.

5. Lack of Oversight and Supervision

Supervisors play a key role in ensuring that safety procedures are followed, risks are addressed in real time, and workers have the support they need to perform tasks safely. Unsafe behavior may go unchecked without consistent oversight, and early warning signs of equipment or procedural failure may be missed.

The Relationship Between Incident Prevention and Risk Management

Risk management and incident prevention are closely connected. The process begins with risk identification, recognizing potential hazards that could lead to harm, damage, or disruption. This step allows organizations to take action before any negative outcome occurs.

When risks are identified early, they can be assessed and prioritized based on their likelihood and severity. Once prioritized, control measures can be introduced to reduce or eliminate those risks. This proactive approach reduces the chance of incidents and supports a safer working environment.

Risk management is also essential for legal and regulatory compliance. Many countries and industries have specific safety laws and standards that require organizations to identify and control risks.

For instance, in the United States, OSHA (Occupational Safety and Health Administration) mandates employers to provide a workplace free from recognized hazards. ISO 45001 is an international standard that outlines requirements for an occupational health and safety (OH&S) management system. It helps organizations systematically reduce workplace risks and improve employee safety.

By integrating risk management into daily operations, businesses prevent incidents and fulfill their legal responsibilities. Non-compliance with such standards can lead to penalties, lawsuits, or reputational damage. Therefore, aligning risk management practices with safety regulations is a preventive and strategic necessity.

Essential Components of a Risk Management Plan

A well-structured risk management plan provides a clear roadmap for identifying, analyzing, mitigating, and monitoring workplace risks. Each component plays a specific role in minimizing the likelihood and impact of incidents.

1. Risk Identification

Risk identification is the first and most critical step. It involves systematically identifying all possible sources of harm in the workplace. This can be done through site inspections, where safety officers or supervisors physically examine work areas, equipment, and processes for potential hazards.

Reviewing historical data such as past incident reports, maintenance logs, and safety audits also helps uncover recurring or overlooked issues. Additionally, employee input is a valuable source of information, as workers often notice day-to-day risks that may not be obvious to management. Encouraging staff to report hazards or near-misses creates a more informed and inclusive safety culture.

2. Risk Assessment

Once risks are identified, they must be assessed to determine their potential impact and how likely they are to occur. This is often visualized using a risk matrix, which categorizes risks based on two key dimensions: likelihood (how likely a risk could happen) and impact (the severity of its consequences).

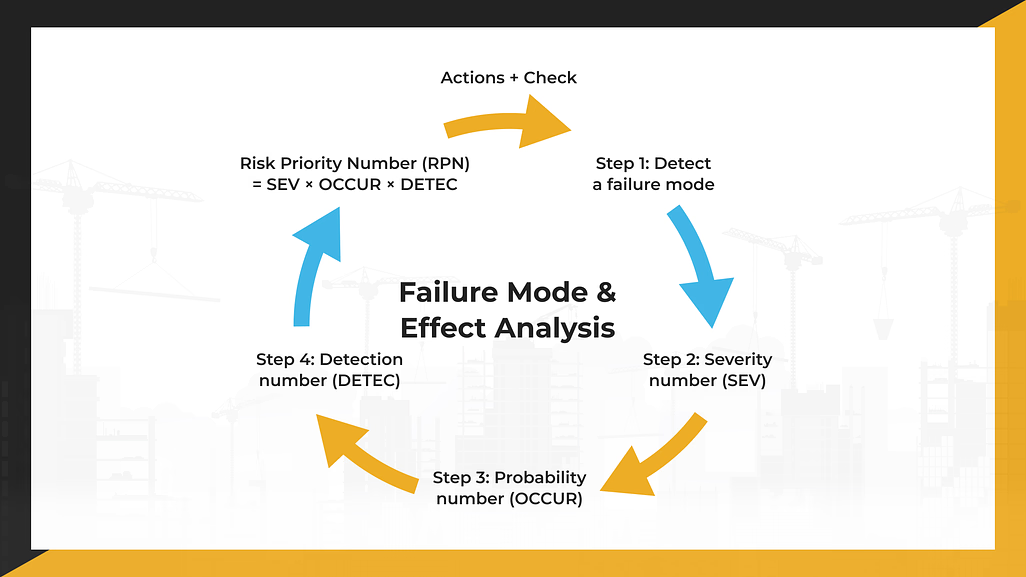

For example, a highly likely but low-impact event might be treated differently from a rare but catastrophic risk. Organizations may use structured techniques like Failure Mode and Effects Analysis (FMEA) to prioritize risks further.

This method involves analyzing each potential failure point within a process, identifying the causes and consequences of those failures, and assigning a priority score based on severity, occurrence, and detection. This ensures that the most critical risks receive immediate attention and resources.

3. Risk Mitigation Strategies

After assessing the risks, the next step is implementing appropriate control measures. These are often categorized by the hierarchy of controls, which prioritizes risk mitigation methods based on their effectiveness:

- Elimination involves removing the hazard entirely from the workplace. For instance, if a toxic chemical is no longer required for a process, discontinuing its use eliminates the associated risk.

- Substitution is replacing a hazardous substance or process with a less dangerous one. An example would be using a non-flammable cleaning solvent instead of a flammable one.

- Engineering Controls aim to isolate people from the hazard through physical modifications. This includes installing machine guards, improving ventilation systems, or automating high-risk tasks.

- Administrative Controls involve changes to workplace policies, procedures, or training. Examples include rotating job roles to minimize exposure, implementing standard operating procedures, and setting clear safety guidelines.

- Personal Protective Equipment (PPE) is the last line of defense and should only be used when other controls are insufficient. PPE includes gloves, helmets, safety goggles, and protective clothing.

Implementing multiple layers of controls ensures a more comprehensive risk reduction strategy.

4. Monitoring and Review

Risk management is not a one-time task; it requires ongoing monitoring and review to remain effective. Organizations should establish safety performance indicators (KPIs) to measure how well risks are controlled. A standard metric is the Lost Time Incident Rate (LTIR), which tracks the number of work-related injuries resulting in time off.

In addition, periodic audits and workplace inspections help ensure that safety procedures are followed and no new risks have emerged. Continuous improvement can be achieved by applying the PDCA (Plan-Do-Check-Act) cycle, which involves planning safety actions, implementing them, evaluating outcomes, and making necessary adjustments. This iterative process strengthens the overall risk management system over time.

Essential Strategies to Prevent Workplace Incidents

Preventing incidents requires proactive planning, employee involvement, technology use, and emergency readiness. The following strategies are essential for creating a safe and prepared work environment.

1. Start with Consistent Training and Awareness

Regular training is essential to ensure all employees understand how to perform their tasks safely. This includes educating them about potential hazards, safe operating procedures, and how to respond in an emergency. Training should be conducted during onboarding and refreshed periodically to keep safety knowledge current.

For example, employees working with heavy machinery, hazardous chemicals, or electrical systems may require specialized instruction and hands-on simulations. Customized training ensures that workers are equipped with the knowledge specific to their job roles and environments.

2. Establishing a Strong and Accountable Safety Culture

Building a strong safety culture is a key part of long-term incident prevention. This starts with leadership commitment when management consistently prioritizes safety, it sets a clear example for the rest of the organization. Leaders should allocate resources for safety programs, address safety concerns promptly, and recognize safe behavior.

When workers are actively involved in safety efforts, such as participating in safety committees or hazard identification, they take greater ownership of workplace safety. Encouraging employees to report incidents or near-misses without fear of punishment supports a “no-blame” culture.

3. Enhancing Safety Through Technology and Data-Driven Insights

Modern technology plays a vital role in identifying and preventing potential incidents. AI and IoT (Internet of Things) devices enable predictive maintenance, where sensors monitor equipment conditions and alert teams before failures occur. This reduces the risk of machine-related accidents.

Safety dashboards consolidate real-time data from various sources, such as incident reports, audit findings, and sensor readings. These dashboards allow safety teams and managers to track performance, spot trends, and respond quickly to potential risks. Automated alerts and notifications also help teams take immediate corrective actions when thresholds are exceeded or anomalies are detected.

4. Ensuring Readiness Through Structured Emergency Planning

Organizations must have evacuation plans that clearly outline exit routes, assembly points, and emergency personnel’s roles. These plans should be communicated to all staff and posted in visible areas.

Regular emergency drills, such as fire, earthquake, or lockdown simulations, help employees practice responses and reduce confusion during real events. Additionally, forming dedicated emergency response teams ensures that trained personnel are available to manage critical situations until professional responders arrive. If needed, these teams should be equipped and trained to handle first aid, fire extinguishing, or equipment shutdowns.

Benefits of Effective Risk and Incident Management

Below are the core advantages of a well-executed risk and incident management strategy.

1. Reduced Downtime and Costs

When risks are identified and addressed early, the chances of incidents disrupting operations are significantly reduced. This means fewer equipment breakdowns, delays, and workplace injuries.

Preventing incidents also helps avoid unplanned maintenance, insurance claims, legal fees, and medical expenses. As a result, the organization experiences lower operating costs and maintains business continuity.

2. Increased Employee Morale and Trust

Workers feel more secure and supported when they see that risks are managed effectively and that their safety is prioritized. This leads to higher morale, improved job satisfaction, and greater trust in management. Employees are also more likely to follow safety procedures and participate in safety initiatives when they believe their well-being is genuinely cared for.

3. Regulatory Compliance

Effective risk and incident management helps organizations comply with standards such as OSHA, ISO 45001, or local labor laws. Compliance reduces the risk of penalties, fines, or shutdowns during inspections. It demonstrates the organization’s commitment to legal and ethical standards, essential for long-term sustainability.

4. Brand Reputation and Stakeholder Confidence

Organizations that maintain safe and responsible operations build a stronger reputation with customers, investors, and partners. Stakeholders are more likely to support a company that consistently avoids major incidents, manages risks transparently, and complies with regulations.

A good safety record enhances credibility during audits, contract bids, or public disclosures. Ultimately, strong risk management strengthens stakeholder confidence and contributes to long-term business success.

Common Challenges and How to Overcome Them

Despite best efforts, organizations often face challenges in implementing effective risk and incident management. Here’s how to address them

1. Resistance to Change

One of the most common barriers is employee or managerial resistance to new safety policies, procedures, or technologies. People are often comfortable with familiar routines and may see safety changes as unnecessary or disruptive.

Clear communication is essential. Explain the reasons behind the changes and their benefits, such as fewer injuries and smoother operations. Involving employees early, through feedback, pilot programs, or safety committees, can also improve acceptance. Change is easier when people feel heard and included.

2. Budget Constraints

Some organizations hesitate to invest in risk management due to limited budgets. Safety equipment, software, training programs, and process upgrades may seem expensive, especially in the short term.

Focus on the return on investment (ROI) of safety initiatives. Preventing even a single incident can save thousands in medical costs, legal fees, and lost productivity. Present data and case studies showing how safety investment leads to long-term financial savings and improved efficiency. Cost-effective solutions like internal training or phased implementations can also be considered.

3. Lack of Leadership Buy-In

Without support from senior management, safety programs often lack the authority or resources needed to be effective. Leaders may underestimate risks or prioritize short-term goals over long-term safety planning.

Show how safety aligns with business goals. This includes reducing downtime, protecting assets, and maintaining compliance. Offering leadership training on risk management and safety responsibilities can help build awareness. Also, demonstrate how safety metrics, like reduced incidents or improved audit scores, contribute to performance outcomes.

4. Integrating Safety into Business Metrics

Sometimes, safety is seen as a separate function rather than part of everyday operations. This separation can weaken its importance in decision-making.

Integrate safety performance into Key Performance Indicators (KPIs) across departments. For example, safety goals can be linked to operational targets, such as zero injuries or 100% training completion rates. When safety becomes part of individual and team evaluations, it gains more visibility and accountability.

Elevate Your Safety Standards with Expert Support from Safe T Professionals

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s HSE protocols, ensure compliance with industry regulations, and mitigate workplace hazards. Whether you are looking to fill safety-specific roles or need expert consultation to reduce workplace hazards, we are here to help.

Connect with us today!