The construction industry is undergoing a significant transformation. According to Deloitte, the average construction company now uses 6.2 digital technologies, marking a 20% increase over the previous year. McKinsey adds that companies embracing digital transformation can see productivity gains of 14–15% and cost reductions of 4–6%.

Yet, here’s the reality: many construction companies are still managing critical health, safety, and environmental (HSE) risks with outdated, manual systems. Relying on spreadsheets, paper checklists, and reactive safety practices no longer meets the demands of today’s projects, clients, or regulations.

If construction sites are becoming more intelligent and more complex, shouldn’t safety systems evolve too?

Digital transformation in HSE is no longer just a plan. It’s the new standard. Digital transformation in HSE is reshaping how companies protect their people, meet regulatory demands, and deliver sustainable projects.

From real-time risk monitoring to predictive analytics and automated compliance, digital tools are redefining what effective safety management looks like on modern construction sites.

This blog explores how digital technologies are reshaping HSE in construction. It examines why the industry urgently needs this shift, the tools making it possible, the challenges companies face during implementation, and the key trends driving the future of digital HSE.

Digital Transformation in HSE: Essential Components

Digital transformation in HSE refers to the shift from manual, paper-based processes for managing environment, health, and safety (EHS) activities to using modern digital systems. This includes the adoption of cloud-based platforms, mobile applications, Internet of Things (IoT) devices, and AI-powered tools. The goal is to improve safety performance, streamline compliance, and enhance operational efficiency. Here are the core components of HSE digital transformation:

1. EHS Management Software

EHS management software centralizes all EHS activities onto a single platform. It allows companies to manage incidents, track compliance, schedule audits, and generate reports digitally.

Popular solutions like VelocityEHS and Enablon offer features such as incident logging, risk assessments, training management, and real-time dashboards. This helps organizations monitor EHS performance systematically and ensure compliance with industry regulations.

2. Wearable Safety Technology

Wearable devices, such as smart helmets, vests, or wristbands, monitor workers’ physical conditions and the environment around them.

These devices can track vital signs, detect exposure to hazardous substances, and send real-time alerts in case of danger. Wearables improve worker safety by providing early warnings and enabling faster emergency responses.

3. Real-Time Hazard Tracking

Real-time hazard tracking systems utilize IoT sensors and mobile devices to continuously monitor construction sites.

These systems detect risks, such as equipment malfunctions, hazardous weather conditions, or unsafe worker behaviors, as they occur. Immediate alerts enable safety managers to address issues before they lead to incidents, reducing downtime and accidents.

4. Automated Compliance Reporting

Automated reporting tools simplify meeting regulatory requirements. Instead of manually compiling safety reports, digital systems automatically collect and organize data.

They can schedule inspections, document audit trails, and generate compliance submissions in line with OSHA, EPA, and other standards. This reduces administrative workload and minimizes the risk of non-compliance penalties.

5. Predictive Analytics for Risk Prevention

Predictive analytics uses historical safety data and real-time inputs to forecast potential risks. AI algorithms analyze patterns to identify conditions that commonly lead to accidents or compliance failures. By predicting where and when hazards are most likely to occur, companies can take preventive action, allocate resources more efficiently, and reduce incidents before they happen.

The Need for HSE Digital Transformation in the Construction Industry

Digital transformation in HSE is crucial for improving safety, ensuring compliance, and supporting broader business objectives. Here’s why the shift to digital is necessary:

1. High-Risk Work Environment

Construction is consistently ranked among the most dangerous industries. According to the Occupational Safety and Health Administration (OSHA), nearly one in five worker deaths occurs in construction. Common risks include falls, equipment accidents, electrical hazards, and exposure to harmful substances.

Digital HSE solutions provide real-time monitoring, early hazard detection, and faster incident reporting, helping to prevent accidents before they happen and supporting a safer workplace.

2. Increasing Project Complexity

Modern construction projects are larger, more technologically advanced, and often span multiple geographical areas. Managing health, safety, and environmental risks across such complex projects is difficult with manual systems.

Digital platforms enable centralized management of safety protocols, risk assessments, and compliance documentation across different sites, ensuring consistent standards and faster decision-making.

3. Stricter Regulatory Oversight

Regulatory bodies such as OSHA and the Environmental Protection Agency (EPA) are tightening compliance requirements for construction activities. Frequent inspections, detailed reporting obligations, and stricter penalties for violations demand higher levels of HSE diligence.

Digital tools automate compliance tracking, audit preparation, and reporting, reducing administrative burdens and minimizing the risk of costly penalties.

4. Changing Workforce Expectations

The construction workforce is evolving, with younger employees entering the industry who are more familiar with digital tools and expect technology to be part of their working environment.

Providing mobile access to safety checklists, training modules, and real-time hazard alerts through digital platforms meets these expectations and improves workforce engagement in safety programs.

5. Sustainability and ESG Pressures

Construction companies are facing increasing pressure to show a measurable commitment to environmental protection and social responsibility. Stakeholders, including clients, investors, and regulators, now expect clear evidence of sustainable practices, especially as part of Environmental, Social, and Governance (ESG) reporting.

International frameworks and regulations, such as the Paris Agreement and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), are further pushing the industry to adopt cleaner, safer, and more accountable methods. As a result, sustainability is no longer a side goal; it’s becoming a core expectation in modern construction operations.

Digital HSE systems support sustainability goals by tracking carbon emissions, waste management, water usage, and other environmental impacts in real time, making it easier to meet ESG criteria and report transparently.

How Technology Shapes the Future of HSE Standards in Construction?

Here is how new technologies are transforming construction sites into smarter, safer, and more sustainable environments.

1. Digital Modeling

Modern construction projects increasingly rely on digital models to improve planning accuracy and reduce on-site risks.

Tools like Building Information Modeling (BIM) allow project teams to simulate construction activities, spot potential hazards early, and coordinate more effectively across disciplines. Early detection of risks through modeling leads to better safety planning and reduces costly mistakes during construction.

2. Drones for Remote Surveys

Drones are redefining how construction sites are surveyed and inspected. By providing detailed aerial views and capturing site data quickly, drones eliminate the need for workers to enter hazardous areas.

This shift improves worker safety and also speeds up the inspection process, helping managers detect issues faster and make more informed decisions.

3. IoT-Enabled Job Sites

The rise of smart construction sites, powered by the Internet of Things (IoT), enables continuous monitoring of workers, equipment, and environmental conditions.

Sensors embedded in safety gear and machinery send live updates on variables like worker location, temperature, and machinery status. This constant stream of data supports faster emergency responses and promotes proactive safety interventions.

4. Augmented Reality for On-Site Learning

Augmented Reality (AR) is changing the way workers are trained to handle risks. Instead of relying only on manuals or classroom sessions, workers can now engage in virtual simulations of hazardous situations.

On-site, AR tools provide live instructions and warnings, helping workers avoid accidents by giving them instant guidance adapted to real-world conditions.

5. Automation

Automation and robotics are taking over some of the most dangerous and repetitive tasks on construction sites. Machines now handle activities like heavy lifting, material placement, and hazardous cleanups.

By reducing human involvement in high-risk operations, construction companies are significantly lowering injury rates while boosting precision and speed.

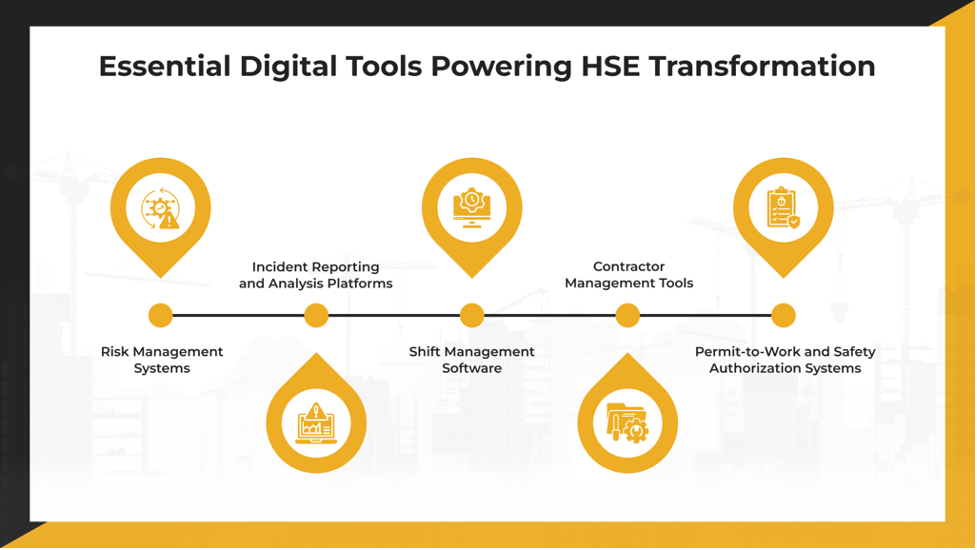

Essential Digital Tools Powering HSE Transformation

Below are the essential digital tools that are shaping modern HSE practices:

1. Risk Management Systems

Risk management systems are digital platforms that help identify, assess, and monitor potential hazards across construction projects.

These systems allow companies to create structured risk assessments, prioritize risks based on severity, and implement mitigation plans. They provide real-time updates, making it easier to track risk controls and adjust safety strategies as project conditions change. This significantly reduces the likelihood of incidents.

2. Incident Reporting and Analysis Platforms

Incident reporting platforms streamline the process of recording, investigating, and analyzing workplace accidents, near misses, and safety violations.

By using digital tools, workers and supervisors can quickly report incidents through mobile apps or web portals. The platforms standardize information collection, ensuring accurate data for root cause analysis. Over time, analyzing incident trends helps organizations identify problem areas and prevent future occurrences.

3. Shift Management Software

Shift management software organizes worker schedules, tracks attendance, and monitors labor compliance across construction sites.

Proper shift planning ensures that workers are not overworked and that there are enough personnel available for safe operations. The software can also flag when certifications or training requirements for specific roles are about to expire, helping maintain a qualified and safety-compliant workforce at all times.

4. Contractor Management Tools

Contractor management tools are digital systems designed to monitor and control the activities of external contractors on a project site.

These tools verify that contractors meet safety, insurance, training, and compliance requirements before starting work. They also track contractor performance and incidents, ensuring third-party workers uphold the same safety standards as internal employees. This reduces overall project risk and improves accountability.

5. Permit-to-Work and Safety Authorization Systems

Permit-to-Work systems manage the approval process for hazardous work activities that require special authorization, such as entering confined spaces, performing electrical maintenance, or operating heavy lifting equipment.

Digital permit systems ensure that all necessary safety checks, risk assessments, and authorizations are completed before dangerous tasks begin. This reduces the chance of accidents related to unauthorized or improperly planned activities. It also improves recordkeeping for regulatory audits and inspections.

Challenges in Implementing HSE Digital Transformation

While the benefits of digital transformation in HSE are clear, construction companies face several real-world challenges when adopting new technologies. Here is a list of a few of them:

1. High Initial Costs

Investing in digital HSE solutions often requires significant upfront expenses. Costs can include purchasing software licenses, upgrading hardware, deploying new IoT devices, and consulting services for implementation. For smaller firms or companies with limited budgets, these initial costs can be a significant barrier, even if the long-term savings are substantial.

2. Resistance to Change

The construction industry has traditionally relied on manual processes and face-to-face communication. Introducing new technologies often faces pushback from both employees and management.

Resistance can originate from a lack of trust in technology, fear of job disruption, or simply a preference for familiar methods. Without strong change management strategies, even the best digital initiatives can fail.

3. Integration with Existing Systems

Many construction companies already use enterprise resource planning (ERP) systems, customer relationship management (CRM) systems, or project management tools.

Integrating new HSE platforms with these existing systems can be technically complex and time-consuming. Poor integration can lead to data silos, duplicate work, and inefficiencies, reducing the effectiveness of the digital transformation.

4. Data Privacy and Cybersecurity Risks

As more safety data is collected and stored digitally, concerns about data privacy and cybersecurity grow. Construction companies may become targets for cyberattacks, risking the disclosure of sensitive worker information and compliance records.

Protecting digital assets requires investment in cybersecurity measures, regular audits, and clear data management policies.

5. Skill Gaps and Training Needs

Adopting digital HSE tools requires a workforce that is comfortable with technology. Many workers, especially those with years of experience in traditional methods, may lack the digital skills needed to use new platforms effectively.

Companies must invest in comprehensive training programs to ensure both field workers and managers can use the systems confidently and correctly. Collaborating with Gallagher Bassett, Safe T Professionals is essential in enhancing workplace safety through expert training and staffing solutions. Their onsite, in-person, and hybrid training courses, led by certified professionals, provide workers with hands-on knowledge and real-world applications for hazard prevention.

6. Selecting the Right Solutions

The growing number of digital HSE products can make it difficult for companies to choose the right tools. Without a clear strategy, organizations risk adopting multiple platforms that overlap in functionality or fail to integrate smoothly. This tool overload increases costs, confuses users and reduces adoption rates.

How to Successfully Implement HSE Digital Transformation in Your Organization?

Below are essential steps to help construction companies implement HSE digital solutions successfully.

1. Start Small with Pilot Programs

Begin by testing digital solutions on a small scale, such as at a high-risk site or a single department. Pilot programs enable companies to evaluate the effectiveness of new tools, identify potential issues early, and make necessary adjustments before wider deployment.

2. Secure Leadership Buy-In

HSE’s digital transformation must have the active support of senior management. When leadership openly champions new safety initiatives, it sets the tone across the organization. Leadership buy-in ensures that necessary resources are allocated, roadblocks are removed, and HSE objectives are prioritized alongside business goals.

3. Focus on Employee Training and Engagement

Invest in programs that build digital literacy and help workers understand the purpose and benefits of new tools. Digital tools are only practical if workers know how to use them correctly.

Training programs should be practical, hands-on, and tailored to different roles. Engaging employees in the transition, gathering feedback, and recognizing their input can improve adoption rates and create a more safety-conscious culture.

4. Choose the Right Vendors and Scalable Solutions

Select HSE platforms that can integrate with existing systems and scale as the company’s needs grow. Choosing flexible, interoperable solutions helps avoid future technology conflicts and protects your investment over time.

Vendor reliability, ongoing support, data security standards, and customization options should be significant factors in the decision-making process. A strong foundation in technology selection reduces the risk of system failures and inefficiencies.

5. Commit to Continuous Improvement

Use the data collected through digital HSE systems to review and refine safety strategies regularly. Regularly analyzing incident data, audit results, and risk reports helps companies spot trends, measure performance, and adjust safety practices proactively. Digital tools should not be seen as one-time installations but as ongoing drivers for performance improvement.

6. Manage Change Effectively

Implement structured change management processes to guide the organization through the transition. Clear, transparent communication about why changes are being made, what the benefits are, and how workers will be supported is critical. Companies should identify change champions within teams, provide continuous updates, and offer support channels to ease the transition.

Future Trends in HSE Digital Transformation

As the construction industry moves toward smarter and safer practices, here is a list of a few of these trends that will shape the future of HSE standards:

1. AI for Predictive Safety

Artificial Intelligence (AI) is becoming an essential tool for identifying safety risks before incidents occur. By analyzing historical data, site conditions, and worker behavior patterns, AI systems can predict where accidents are most likely to happen.

This allows safety managers to take proactive measures, such as adjusting work schedules, improving site layouts, or targeting specific training sessions, to prevent accidents before they occur.

2. Mobile-First EHS Platforms

Mobile devices are now central to EHS management. Inspections, incident reporting, audits, and hazard assessments can all be conducted directly through smartphones or tablets.

This shift to mobile-first platforms speeds up communication, ensures that safety protocols are followed on-site in real time, and makes it easier to document and track compliance activities. Mobile access also empowers field workers to participate more actively in safety programs.

3. AR/VR for Safety Training

Augmented Reality (AR) and Virtual Reality (VR) technologies are transforming how construction workers are trained. Instead of traditional classroom sessions, workers can experience interactive, simulated environments that replicate real-world hazards.

VR safety training modules enable workers to practice emergency procedures, identify hazards, and learn proper responses without actually being exposed to danger. This method increases engagement and improves retention of critical safety knowledge.

Elevate Your Workplace Safety with Expert HSE Consulting and Staffing

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s HSE protocols, ensuring full compliance with industry regulations and mitigating workplace hazards. Whether you are looking to fill safety-specific roles or need expert consultation to mitigate workplace hazards, we are here to help.

Connect with us today!