According to OSHA (Occupational Safety and Health Administration), over 2.8 million nonfatal workplace injuries are reported in the United States each year, many of which could be prevented through proactive safety measures.

One of the most effective ways to prevent accidents is to focus on behaviors before they lead to harm. This is where Behavior Safety Audits (BSA) come into play.

Unlike regular inspections that concentrate solely on hazards or compliance paperwork, BSAs take a closer look at how work is performed, identifying safe and unsafe behaviors in real time and correcting them before they cause injury.

By observing real tasks, giving immediate feedback, and capturing accurate data, organizations can create a safety program that acts before an incident happens, not after. It turns safety from a reactive process into a proactive culture.

In this blog, we’ll explore precisely what a BSA is, why it matters, how to implement it effectively, and how technology can take it to the next level, so your workplace safety program meets standards.

Behavior Safety Audits (BSA): What They Are and Why They Matter

A Behavior based Safety Audit (BSA) is a structured, non-punitive process used to observe how work is carried out in real conditions. During a BSA, an observer focuses on predefined critical behaviors, specific actions, or steps that have been identified as essential for safe work.

The observer notes whether each behavior is performed safely, provides immediate feedback, and records the results. The goal is not to assign blame but to gather accurate information about work practices, address unsafe behaviors in real time, and identify barriers that prevent safe actions.

BSAs are essential because they generate leading indicators, and this data can be used to identify and address risks before an incident occurs. Instead of only tracking injuries or accidents after they happen, BSAs allow organizations to:

- Identify unsafe trends early: Regular observations reveal patterns in unsafe actions or missed steps, which can be corrected before they result in harm.

- Improve safety practices in real time: Immediate, respectful feedback during the audit helps reinforce correct behaviors and address unsafe ones without delay.

- Target resources effectively: By tracking which tasks or areas have the most at-risk behaviors, organizations can focus training, engineering controls, or procedural changes where they are most needed.

- Measure program effectiveness: Metrics such as participation rates, percentage of safe acts, and quality of feedback show whether safety initiatives are being implemented consistently and effectively.

This helps reduce incidents, supports compliance with safety management systems, and builds a more reliable safety culture over time.

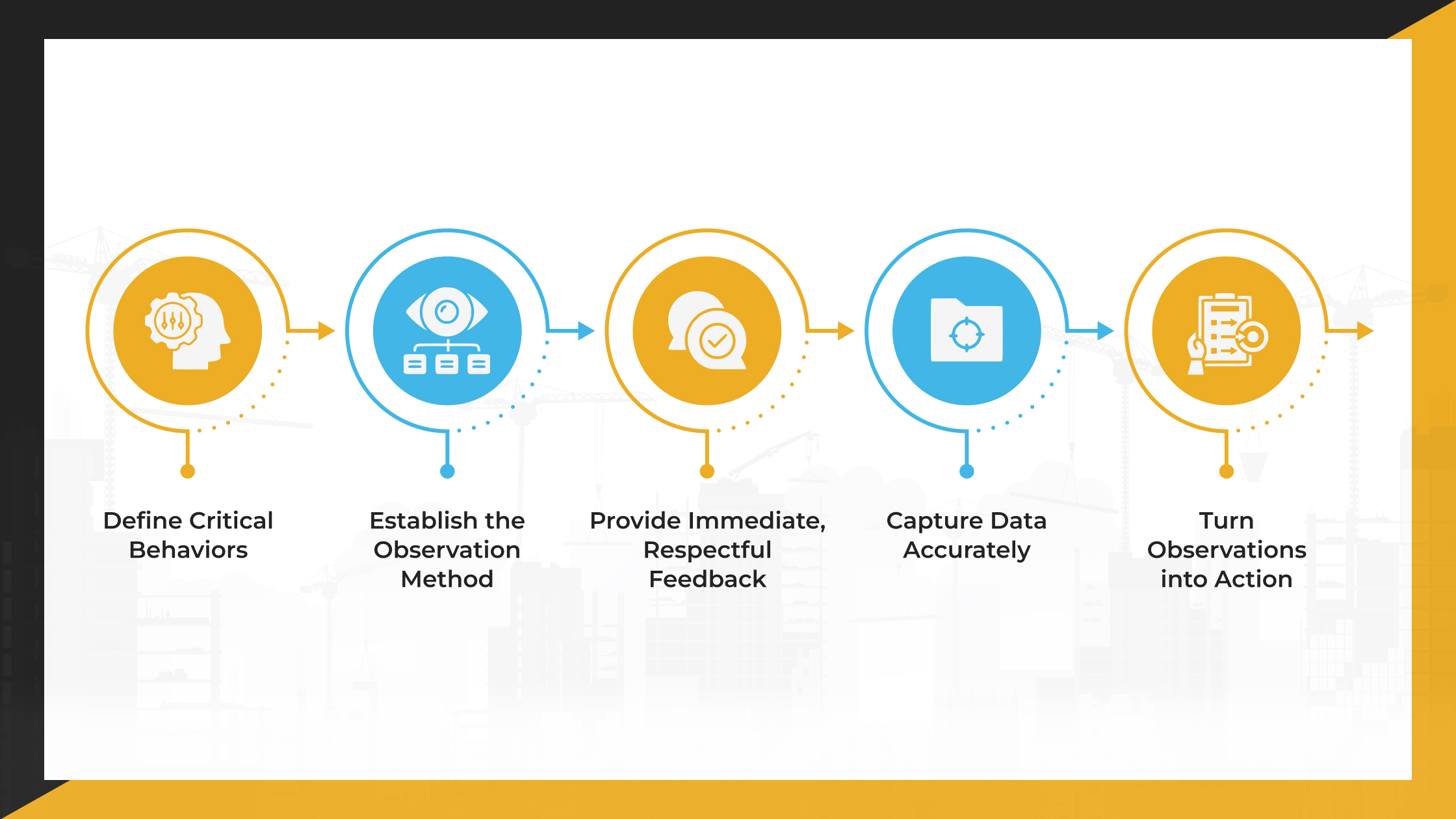

Core Elements of an Effective BSA Program

A Behavior Safety Audit (BSA) is most effective when it is built on a clear structure and consistent practices. Below is the list of elements that ensure the program captures reliable data, provides valuable feedback, and leads to real safety improvements.

1. Define Critical Behaviors

Identify specific actions or steps that are essential for safe work in your operations. These should be based on your highest-risk tasks and past incident data.

Write clear, observable definitions so anyone conducting an audit can mark behaviors as “safe” or “at risk” without guessing. Keep the list focused on behaviors that directly prevent incidents (e.g., using fall protection, proper lifting technique, lockout/tagout verification).

2. Establish the Observation Method

Decide who will perform the observations, how often they will occur, and how you will select which tasks or locations to observe.

Use a mix of trained supervisors and peer observers to improve trust and accuracy. Rotate observers to reduce bias and cover different shifts or work areas. Ensure confidentiality and focus on behaviors, not singling out individuals for discipline.

3. Provide Immediate, Respectful Feedback

Feedback should be given right after the observation, while the task is still fresh. Reinforce correct behaviors to encourage repetition.

When unsafe behaviors are observed, ask about the reason or barrier, then discuss a safer alternative. Keep the conversation respectful and brief so work can continue without unnecessary disruption.

4. Capture Data Accurately

Use a simple checklist to record observations and ensure consistency. Track the percentage of safe acts for each behavior observed.

Record the reason or barrier for any unsafe behavior (e.g., lack of tools, unclear procedure, time pressure). Include a section for free-text hazard notes so observers can report issues not covered by the checklist.

5. Turn Observations into Action

Review observation data regularly and use it to make fundamental changes. Look for patterns in unsafe behaviors and address the root causes.

Apply the hierarchy of controls; fix hazards through engineering or procedural changes rather than relying only on reminders. Assign corrective actions with precise deadlines and follow up until the issue is resolved.

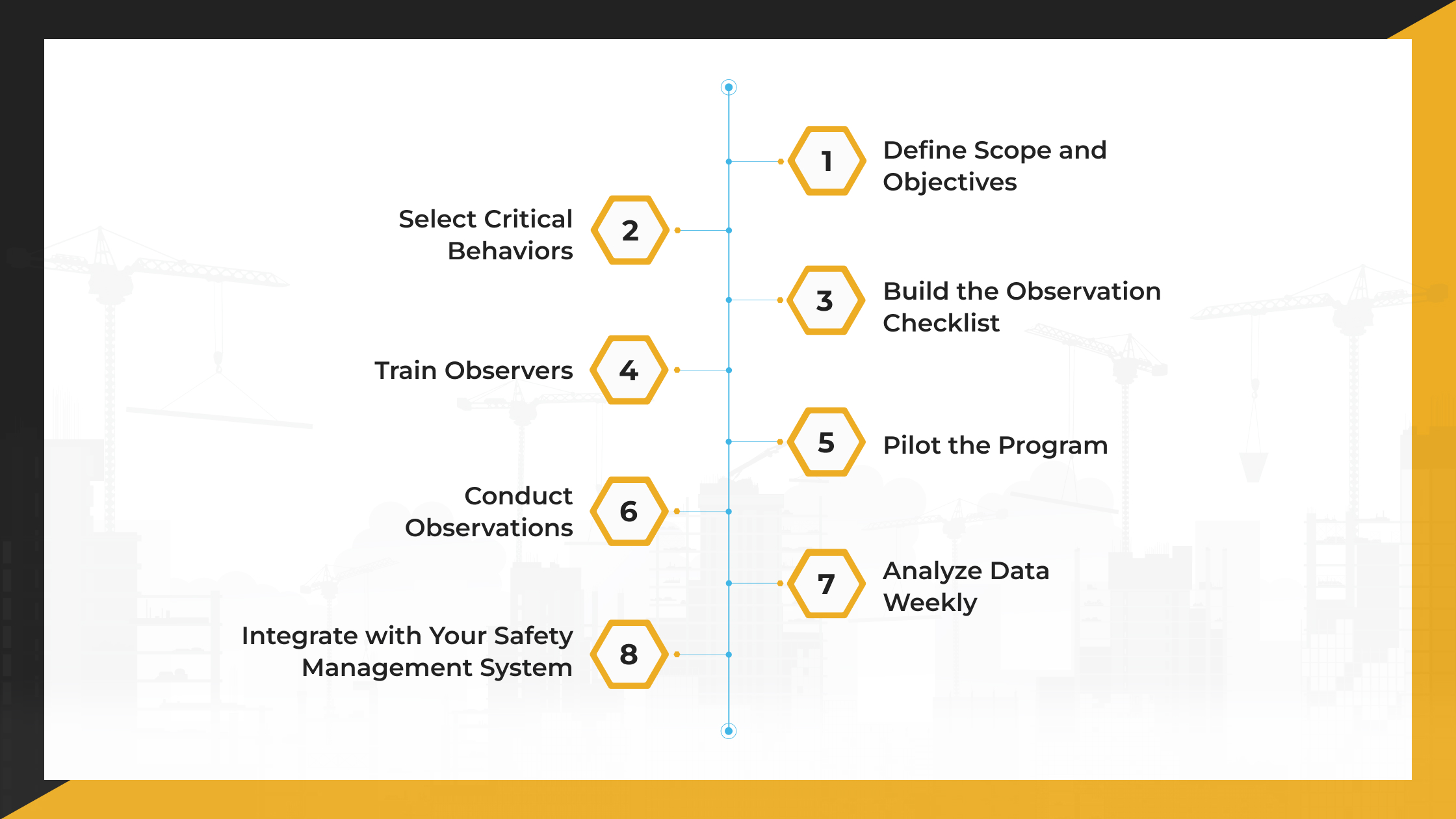

Implementing a Behavior Safety Audit (BSA): The Complete Process

Implementing a Behavior Safety Audit requires a clear plan so that observations are consistent, data is accurate, and results lead to real safety improvements. Below are the essential steps to set up and run a BSA effectively.

1. Define Scope and Objectives

Decide which tasks, areas, or operations the BSA will cover. Focus on high-risk activities and link the program to your risk register and overall safety goals. Clear scope and objectives help ensure the audit captures the most relevant safety behaviors.

2. Select Critical Behaviors

Identify the specific actions that will be observed. Use risk assessments and incident history to choose behaviors that have the most significant impact on preventing injuries. The Health and Safety Executive (HSE) recommends making these behaviors observable, specific, and directly linked to risk control.

3. Build the Observation Checklist

Create a simple checklist that lists each critical behavior with a yes/no option and space for comments. This helps standardize observations and reduce bias. Include a section for noting barriers or hazards that may not be on the list.

4. Train Observers

Train all observers to ensure consistent and fair observations. Cover:

| Aspect | Description |

| Calibration | Ensuring all observers interpret and assess behaviors consistently in the same way. |

| Ethics | Maintaining honesty, fairness, and integrity throughout all observations. |

| Psychological Safety | Creating an environment where workers feel comfortable and secure while being observed. |

| Non-Punitive Stance | Focusing on improvement and learning rather than punishment, as recommended by the CDC and NIOSH. |

5. Pilot the Program

Run the BSA for about two weeks in a small area or team. Use this period to check inter-rater reliability (whether different observers record similar results for the same behavior) and adjust wording or processes for clarity.

6. Conduct Observations

Carry out observations according to the set schedule. Provide micro-coaching on the spot to reinforce safe actions and address unsafe ones. Record reasons for dangerous behaviors and, where possible, remove identified barriers immediately.

7. Analyze Data Weekly

Review data every week to track. Weekly reviews should focus on identifying patterns in unsafe behaviors, spotting emerging risks, and verifying that corrective actions are being implemented effectively. Use these sessions to engage both management and frontline teams, discuss recent observations, and share quick wins to maintain momentum.

8. Integrate with Your Safety Management System

Feed BSA results into your Occupational Health and Safety Management System (OHSMS). Use the Plan-Do-Check-Act (PDCA) cycle to review data, make improvements, and include findings in management reviews. This ensures the program remains effective and evolves with changing risks.

Behavior Safety Audit (BSA) Metrics That Drive Real Improvement

Measuring the right metrics ensures your Behavior Safety Audit (BSA) is effective and delivers actionable results. Metrics should be a mix of leading, lagging, and quality indicators so you can see both early warning signs and long-term outcomes.

1. Leading Indicators

These measure safety activities and conditions before an incident occurs. They help identify and address risks early, which is why OSHA recommends tracking them.

- Observation participation rate – The percentage of planned observations completed within the set period. Low rates can indicate scheduling or resourcing issues that need attention.

- % safe by behavior – The percentage of observed behaviors that meet the defined safe standard. A drop in this number signals where targeted improvements are needed.

- Number of barriers removed – The count of hazards or process issues corrected as a direct result of BSA findings. This measures the program’s impact on real-world safety improvements.

- Time to close corrective actions – The average number of days it takes to complete and verify fixes after they are identified. Shorter closure times mean faster risk reduction.

2. Lagging Indicators

Lagging indicators reflect events that have already happened. They help understand trends but should be used alongside leading indicators to avoid reactive-only management.

- TRIR (Total Recordable Incident Rate) – Shows the rate of OSHA-recordable injuries/illnesses.

- LTIR (Lost Time Incident Rate) – Shows incidents that resulted in lost work time.

- Severity – Measures the seriousness of injuries, such as average lost workdays per incident.

These should be interpreted carefully to avoid “gaming” the numbers and should never be the sole measure of safety performance.

3. Quality Indicators

These assess whether the BSA process itself is being carried out effectively and consistently.

- Inter-rater reliability checks – Ensuring that different observers record the same outcome for the same observed behavior. This helps maintain data accuracy.

- Percentage of observations with coaching delivered – The proportion of observations where the observer gave immediate, specific feedback. High percentages indicate the program is being used as a real-time improvement tool rather than just a data collection exercise.

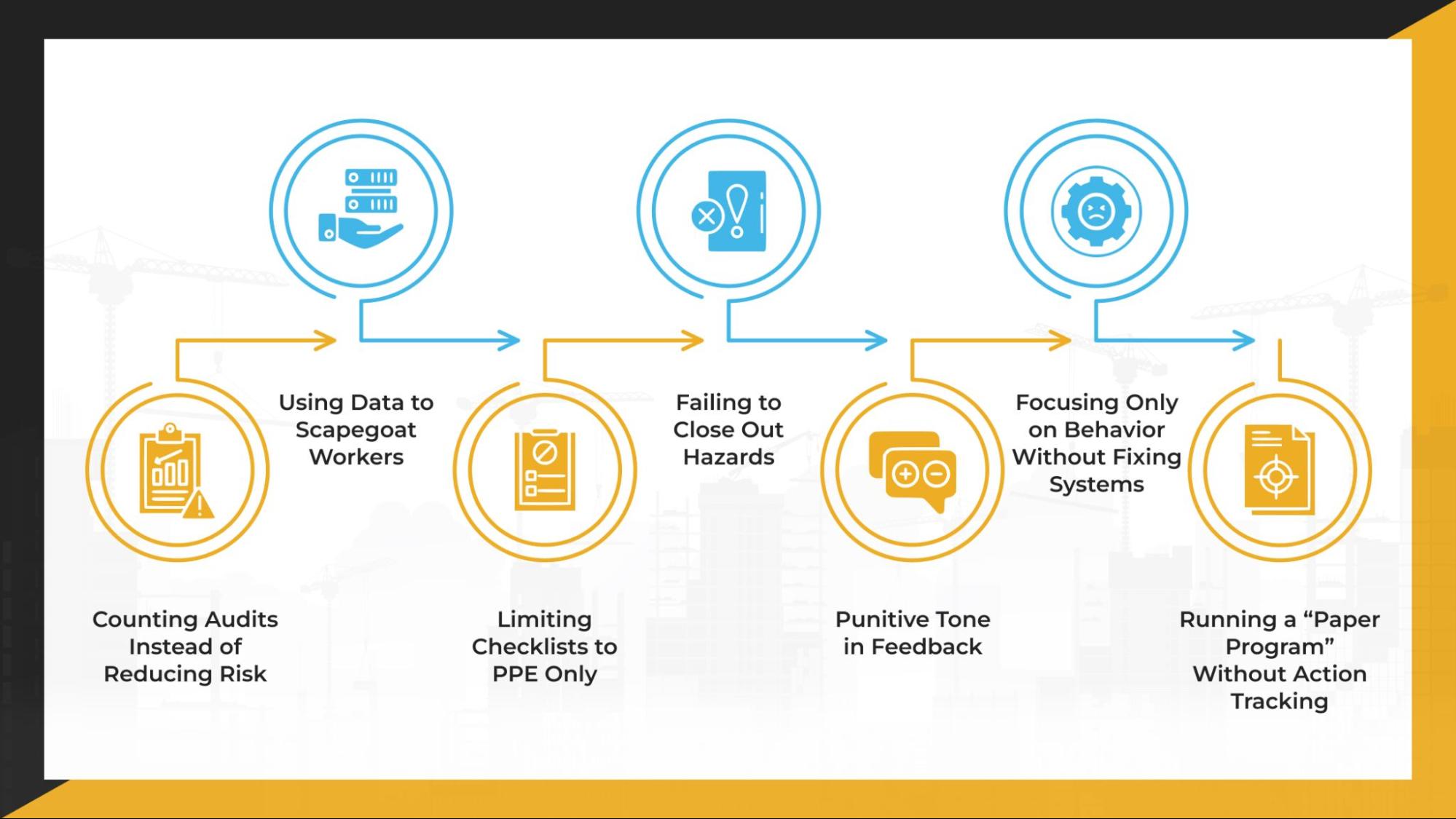

Common Behavior Safety Audit Pitfalls and Practical Solutions

A Behavior Safety Audit (BSA) can fail to deliver results if it is poorly designed or mismanaged. Below are common pitfalls, along with practical ways to avoid them, based on guidance from reputable safety sources.

1. Counting Audits Instead of Reducing Risk

Focusing only on the number of checklists completed can create the illusion of progress without improving safety.

Track metrics that reflect actual impact, such as the percentage of safe behaviors and the number of hazards corrected. Make sure every observation leads to useful information and potential improvement, not just a higher count of audits.

2. Using Data to Scapegoat Workers

If BSA data is used to discipline or blame workers, participation will drop, and observation quality will suffer.

Follow a “just culture” approach; focus on fixing systems and removing barriers rather than punishing individuals. Communicate clearly that the audit’s purpose is improvement, not enforcement.

3. Limiting Checklists to PPE Only

Overemphasis on personal protective equipment (PPE) can overlook more serious hazards and unsafe processes.

Include behaviors that address high-risk hazards and their controls, such as lockout/tagout, machine guarding, safe lifting techniques, and line-of-fire avoidance. This ensures the audit addresses the most critical safety issues.

4. Failing to Close Out Hazards

Observations that identify hazards but never lead to fixes reduce credibility and trust in the program. Track corrective and preventive action (CAPA) cycle time and share progress with the workforce. Ensure all identified issues are assigned, resolved, and verified in the field.

5. Punitive Tone in Feedback

Delivering feedback in a blaming or critical manner discourages reporting and openness. Use a coaching approach, acknowledge correct behaviors, ask about reasons for unsafe actions, and work together to find solutions.

6. Focusing Only on Behavior Without Fixing Systems

Correcting worker actions without addressing underlying hazards or system flaws leads to recurring unsafe behaviors. Use observation data to identify systemic fixes, such as better equipment, redesigned processes, or clearer procedures, as OSHA recommends.

7. Running a “Paper Program” Without Action Tracking

If BSA data is collected but not acted on, the program loses credibility quickly. Tie every observation insight to a corrective action with a deadline and follow-up. Make results visible to the workforce so they see the value of the process.

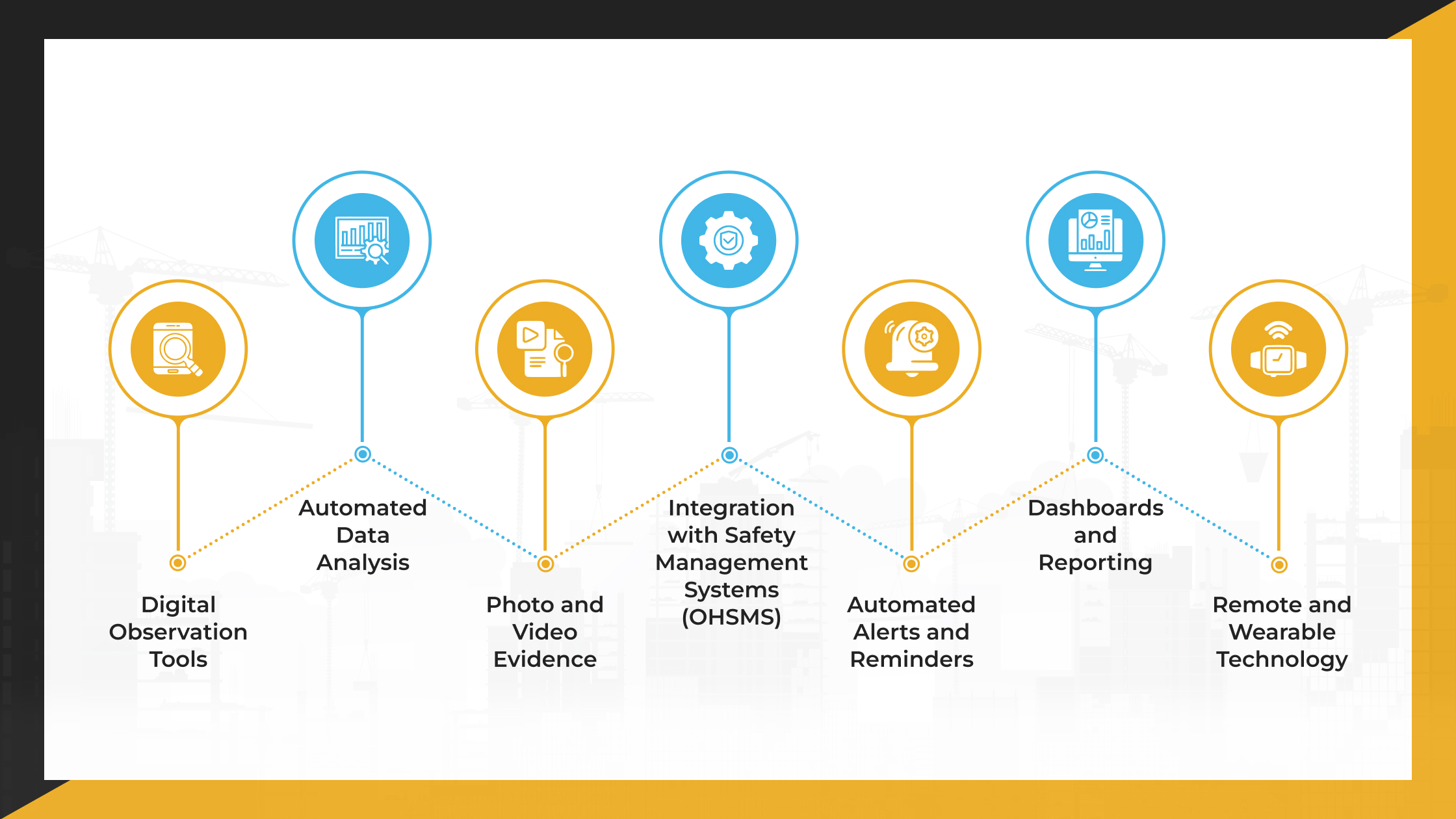

The Role of Technology in Driving Effective Behavior Safety Audits (BSA)

According to a Verdantix report, companies that digitize safety processes can improve incident reporting rates by up to 35% and reduce hazard closure times by as much as 25%, directly strengthening prevention efforts.

1. Digital Observation Tools

Using mobile or tablet-based observation apps allows safety teams to record findings in real time with preloaded checklists, drop-down menus, and voice-to-text features. This eliminates paper-based delays, ensures consistency across observers, and enables instant sharing of results with supervisors and management.

2. Automated Data Analysis

Software platforms can instantly compile observation data, calculate core metrics like participation rate and percentage of safe acts, and highlight recurring issues. Automated analytics not only reduce manual processing errors but also allow safety teams to spot trends weeks earlier than traditional review cycles, leading to faster corrective action.

3. Photo and Video Evidence

Capturing images or short videos during observations provides undeniable visual proof of both safe and unsafe practices. These visuals are powerful for training, as they demonstrate actual worksite conditions.

4. Integration with Safety Management Systems (OHSMS)

Linking BSA data directly into systems like ISO 45001 or ANSI/ASSP Z10 ensures observations feed seamlessly into the Plan-Do-Check-Act (PDCA) cycle. This integration allows for direct assignment, tracking, and closure of corrective actions while maintaining compliance documentation in one place.

5. Automated Alerts and Reminders

Technology can trigger automated notifications when corrective actions are overdue, participation rates drop, or unsafe trends escalate. This reduces the chance of missed follow-ups and keeps the safety process active rather than reactive.

6. Dashboards and Reporting

Real-time dashboards offer an instant snapshot of top at-risk behaviors, open corrective actions, and observation coverage. This visibility enables managers to prioritize resources where they are needed most, resulting in improvement in safety KPI performance after implementing real-time reporting.

7. Remote and Wearable Technology

Wearable sensors and remote observation devices make it possible to monitor high-risk or restricted areas without exposing observers to danger. These tools expand coverage, ensure continuous monitoring, and capture behavioral data in locations that might otherwise go unobserved.

Partner with Safe T Professionals to Strengthen Your Workplace Safety

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s safety protocols and ensure compliance with industry standards. Whether you are looking to fill safety-specific roles or need expert consultation to mitigate workplace hazards, we are here to help.

Connect with us today!