When workplace accidents happen, the focus often falls on broken equipment, unsafe environments, or missed procedures. But one critical piece is frequently overlooked, the human element.

In workplace safety, human factors refer to the range of conditions that influence how people behave on the job. As defined by the Health and Safety Executive (HSE), these factors include environmental, organizational, job-related, and individual elements that impact both performance and safety outcomes. This could be anything from mental fatigue and poor lighting to unclear instructions or inadequate training.

According to the Occupational Safety and Health Administration (OSHA), employers are responsible for providing a safe and healthy workplace. While compliance with OSHA regulations often focuses on physical hazards, many incidents can be traced back to human errors, decisions, actions, or oversights made under pressure, stress, or unclear conditions.

In fact, research suggests that up to 90% of workplace accidents are linked to human error. This makes it clear that understanding human behavior is just as important as guarding against physical risks. This blog examines how recognizing and addressing human factors in safety can lead to improved safety practices, enhanced performance, and healthier work environments.

Frameworks & Models for Understanding Human Factors

To effectively integrate human factors into workplace safety, it is helpful to utilize established models that explain how human behavior interacts with systems and environments. Below are three widely used frameworks that offer practical methods for assessing and improving safety through a human-centered approach.

1. HSE’s Human Factors Model

The Health and Safety Executive (HSE) outlines three key areas that influence human behavior at work:

- Task Factors – These include job design, workload, and the clarity of instructions. Tasks that are too complex, rushed, or poorly defined increase the chance of errors.

- Individual Factors – These cover a worker’s skills, training, experience, and even physical and mental condition. Lack of knowledge or fatigue can impact performance.

- Organizational Factors – These relate to company policies, leadership, safety culture, communication, and supervision. A disorganized or unsupportive environment can lead to unsafe behavior.

This model helps identify where breakdowns occur, at the task level, the individual level, or across the organization.

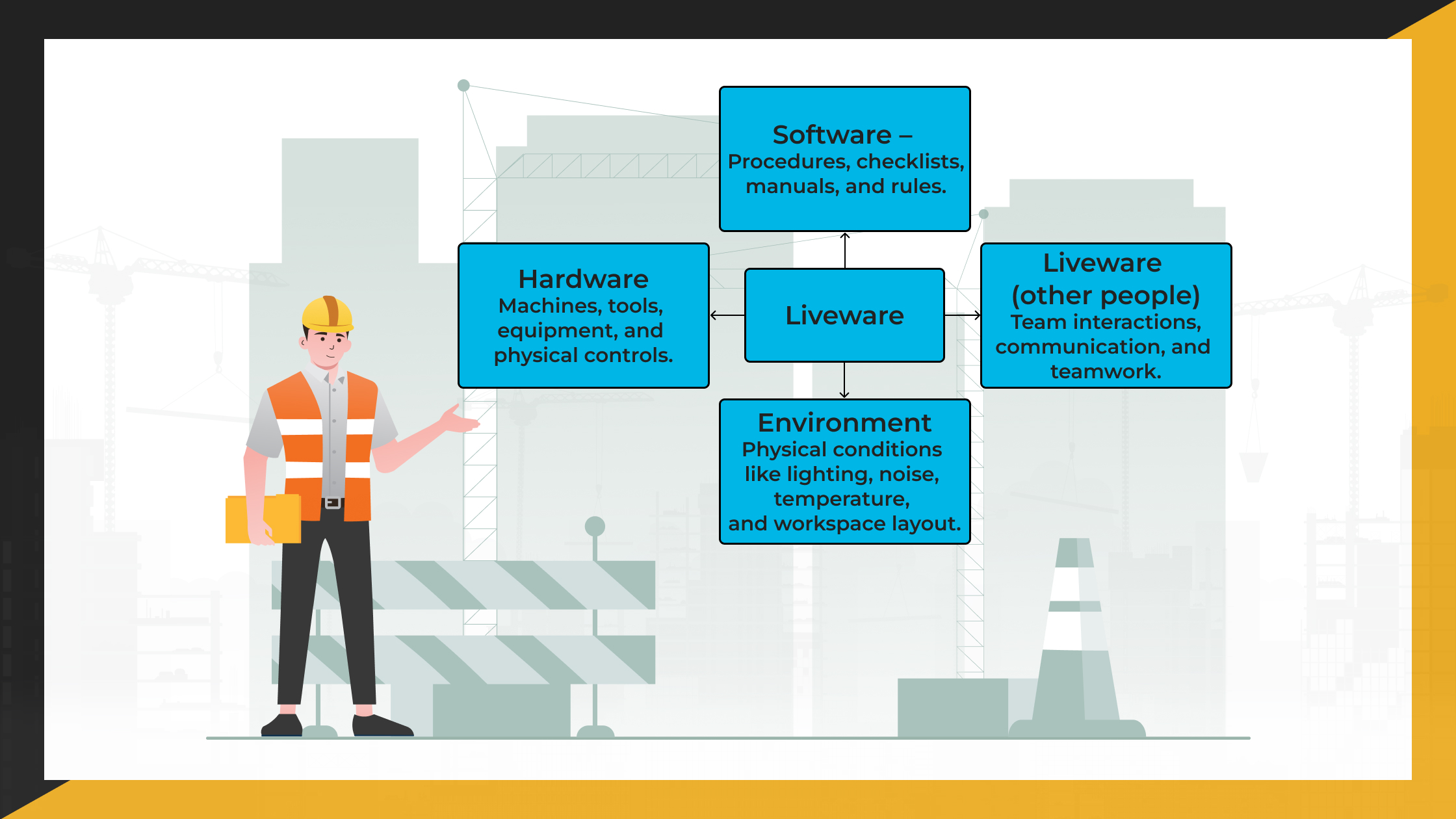

2. SHELL Model

The SHELL model is used to understand how people interact with various parts of a system. The central element is Liveware (the human), which connects with four other components:

- Software – Procedures, checklists, manuals, and rules.

- Hardware – Machines, tools, equipment, and physical controls.

- Environment – Physical conditions like lighting, noise, temperature, and workspace layout.

- Liveware (other people) – Team interactions, communication, and teamwork.

This model emphasizes that mismatches between any of these components and the human can lead to errors or accidents. For example, unclear procedures (Software) or poorly designed tools (Hardware) may cause mistakes even if the worker is trained and alert.

3. HEART (Human Error Assessment and Reduction Technique)

HEART is a method used to estimate the likelihood of human error in a given task. It considers “error-producing conditions” such as:

- Time pressure

- Distractions

- Unfamiliar tasks

- Lack of training

- Fatigue

Each task is assigned a base error rate, and adjustments are made based on the number of these conditions present. This helps safety professionals identify high-risk tasks and apply targeted controls, such as simplifying procedures, adding supervision, or improving training.

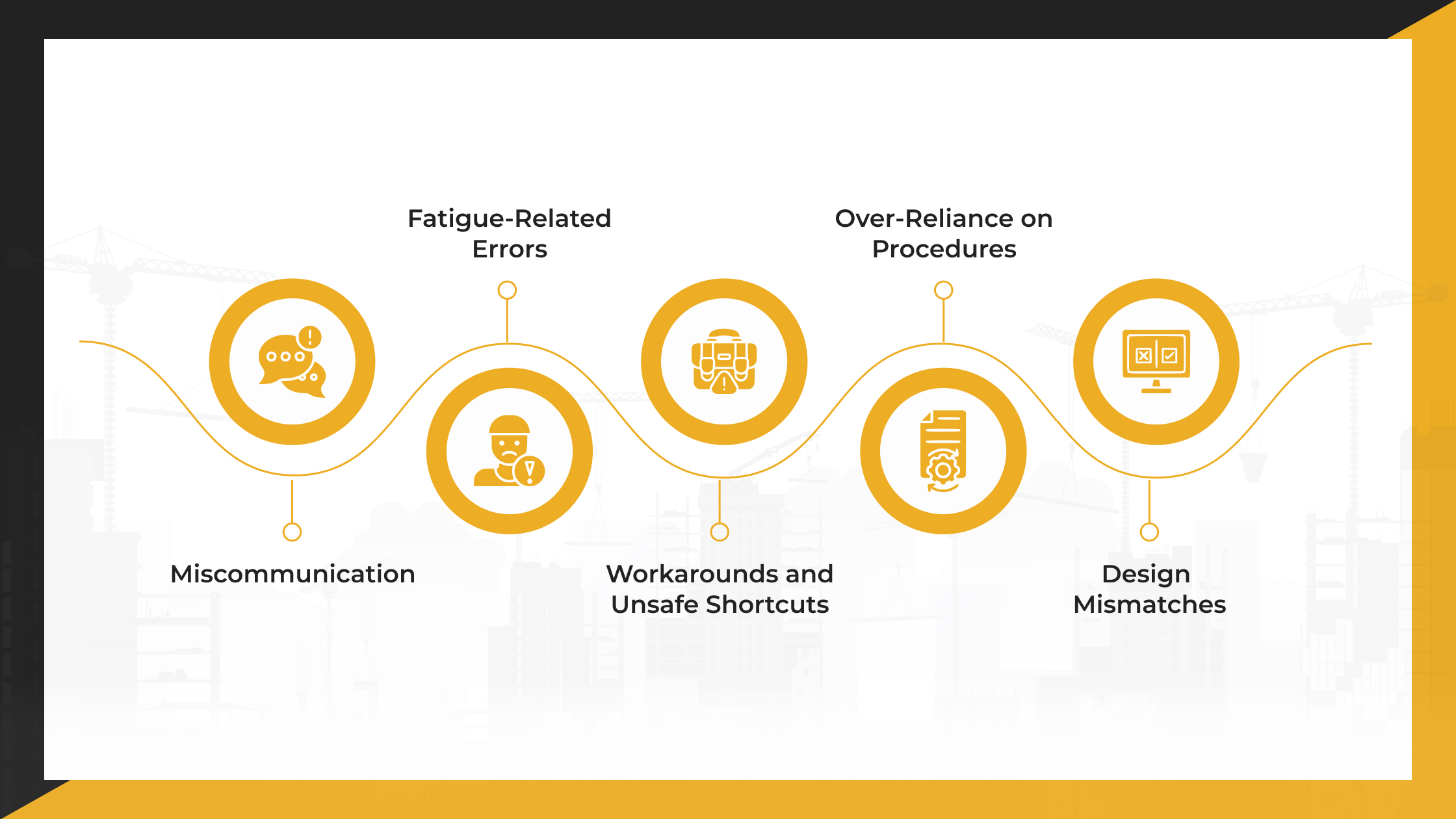

Common Human Factor-Related Failures in the Workplace

When human safety factors are overlooked, even well-designed safety programs can fail to achieve their intended goals. Understanding where things commonly go wrong helps identify hidden risks and take corrective action. Below are some of the most common human factor-related failures observed in workplaces across various industries.

1. Miscommunication

Miscommunication is one of the leading causes of workplace incidents. It occurs when instructions are unclear, incomplete, or misunderstood. This can stem from poor documentation, the use of technical jargon, or the assumption that all workers interpret information in the same way. Language barriers and a lack of feedback loops also increase the chances of error.

For example, a technician misunderstands verbal instructions during a shift change, leading to incorrect equipment settings and a process failure.

2. Fatigue-Related Errors

Long shifts, night work, and high-pressure environments often lead to physical and mental fatigue. Tired workers are more likely to make mistakes, have slower reaction times, and overlook critical steps.

Fatigue is particularly hazardous in jobs that require concentration, coordination, or decision-making under pressure. For instance, an operator misses a critical alarm because they’re working overtime for the third consecutive day.

3. Workarounds and Unsafe Shortcuts

Employees sometimes bypass procedures to save time or meet deadlines. These shortcuts typically emerge when processes are overly complex, unrealistic, or poorly designed.

While they may seem efficient in the short term, they increase the risk of injury, equipment damage, or process failure. For example, a worker disables a machine guard to speed up production, exposing themselves to moving parts.

4. Over-Reliance on Procedures

Having procedures in place is essential, but assuming they will always be followed is a mistake. Some procedures may be too complex, complicated to remember, or not aligned with how work actually happens on the floor.

Without considering human limitations, such as memory and attention span, written rules alone cannot prevent mistakes. For example, a multi-step maintenance checklist is skipped because it’s too lengthy and time-consuming, resulting in a missed inspection point.

5. Design Mismatches

Tools, interfaces, and workspaces that do not match human capabilities can lead to frequent errors or even injuries.

Poor layout, hard-to-read displays, awkward controls, or inaccessible emergency equipment make tasks harder and less safe. An emergency stop button is placed behind the equipment, potentially delaying a response during a critical situation.

Human Factors in Safety: What Drives Safe or Unsafe Behavior at Work

Below are the most significant human factors in safety that have a substantial influence on how work is performed and risks are managed. Incidents are prevented across all levels of an organization.

1. Training

Training ensures that employees know how to perform their tasks safely and correctly. When workers receive proper training, they are less likely to make mistakes that could lead to accidents.

Effective training programs encompass both initial onboarding and ongoing refreshers, covering essential safety procedures, equipment usage, and emergency response protocols.

2. Supervision

Adequate supervision helps maintain safe work practices. Supervisors monitor performance, correct unsafe behavior, and provide guidance.

Poor supervision can lead to rule violations, shortcuts, or the failure to recognize warning signs. Consistent oversight reinforces accountability and ensures that safety protocols are followed.

3. Systems and Processes

Workplace systems, including scheduling, reporting, maintenance routines, and communication channels, significantly impact the safety of task execution. Well-designed systems support error-free work by reducing confusion and delays.

On the other hand, flawed systems can create pressure, cause misunderstandings, or hide critical information, increasing the risk of incidents.

4. Safety Culture

Safety culture refers to the shared values, beliefs, and practices that surround safety within an organization. A strong safety culture means everyone, from top management to frontline staff prioritizes safety.

This includes encouraging hazard reporting, learning from near-misses, and recognizing safe behavior. A poor safety culture often leads to underreporting, complacency, and the normalization of risky behavior.

Why Integrating Human Factors Matters: What You Need to Know

If you’re responsible for workplace safety, team performance, or compliance, understanding human factors in safety is essential. Here’s why this approach can transform the way you manage safety in your organization:

1. Reduce Risk Where It Starts

Accidents don’t just happen; they’re often the result of systems that ignore how people actually work. By accounting for human limitations like fatigue, distraction, or awkward postures, you can prevent many incidents before they occur.

For example, a simple ergonomic workstation design can dramatically reduce repetitive strain injuries and boost overall comfort. The more you tailor tasks and tools to fit the human body and mind, the fewer errors you’ll see.

2. Build a Culture People Trust

People are more likely to follow safety procedures when they feel supported rather than blamed. A strong safety culture starts with recognizing human needs. That means training that makes sense, clear communication, and a work environment that values physical and mental well-being.

When employees see that safety is a shared priority, morale improves and so does accountability. You’re not just reducing accidents; you’re building loyalty.

3. Solve the Root Cause, Not Just the Symptom

When an incident occurs, do you look deeper than the immediate mistake? Human factors help you move past blame and uncover the real issue, whether it’s unclear procedures, poor supervision, or pressure to meet unrealistic deadlines. This mindset shift turns your safety program into a tool for real improvement. Instead of reacting to problems, you prevent them from repeating.

4. Meet Standards and Boost Performance

If you’re working toward ISO 45001 or ANSI/ASSP Z10 compliance, integrating human factors isn’t just recommended, it’s expected.

These standards emphasize the role of people in safety systems. By embedding human-centered practices into your processes, you not only meet regulatory requirements, but you also increase productivity, reduce downtime, and cut costs associated with injuries and absenteeism. It’s a win-win for safety and your bottom line.

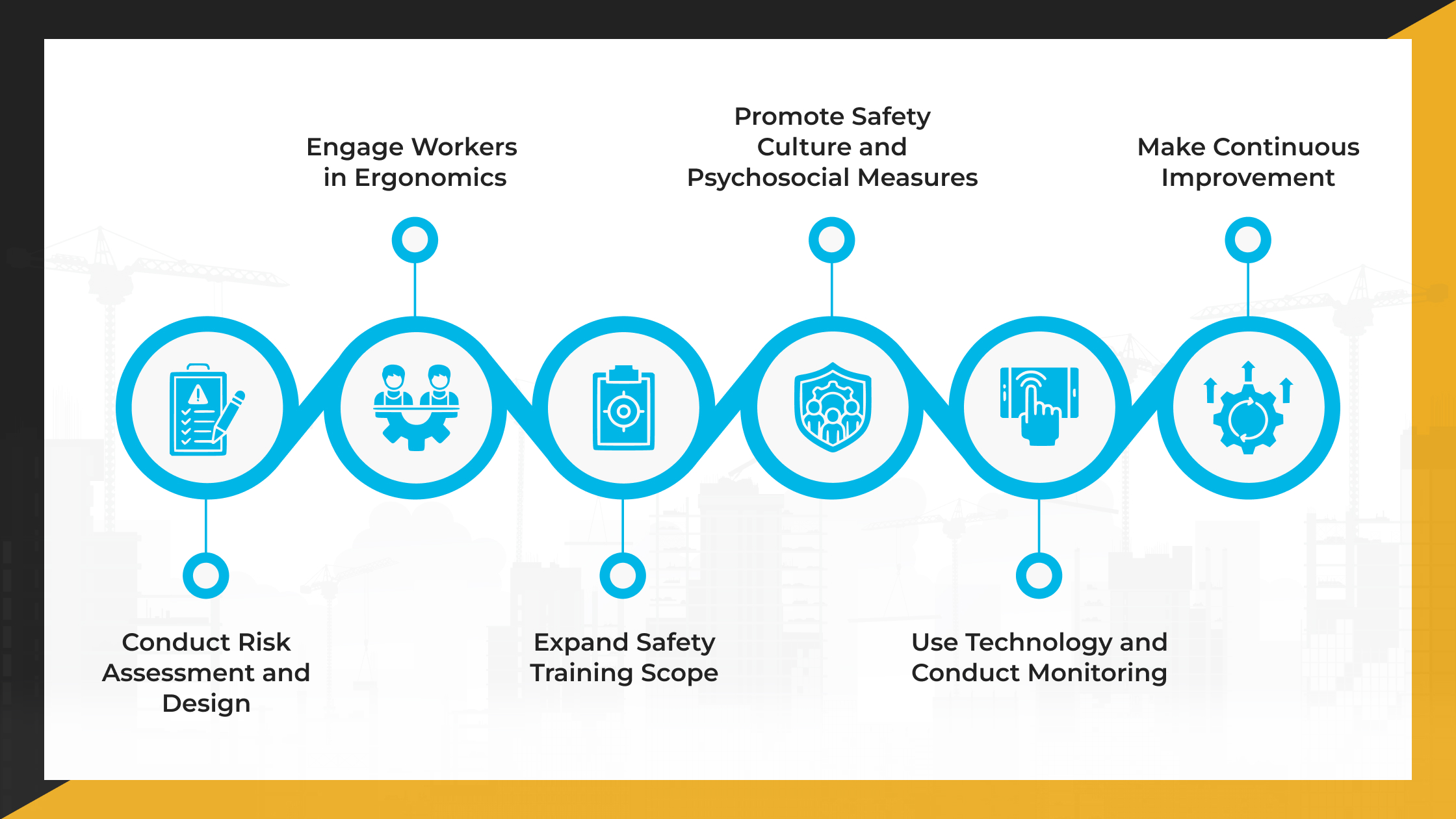

Practical Strategies to Integrate Human Factors into Safety Systems

If you’re aiming to build a safer and more efficient workplace, integrating human factors into your systems and processes is crucial. Below are practical strategies you can start applying across your organization:

1. Conduct Risk Assessment and Design

When conducting hazard analyses or designing jobs and equipment, include human factors in your evaluation. This involves examining how tasks are performed, the physical and cognitive demands involved, and whether tools and systems support human performance.

Adjust layouts, workflows, and equipment design to reduce the chance of errors and fatigue. Simple changes, such as improving visibility or adjusting task sequences, can have a significant impact.

2. Engage Workers in Ergonomics

Involve employees directly in designing safer and more efficient work environments. Form ergonomics committees or feedback groups that include workers from different roles.

These teams can help identify problems with equipment setup, posture, or workflow. Because workers understand the practical challenges of their jobs, their input leads to more effective and accepted solutions.

3. Expand Safety Training Scope

Training programs should encompass more than just technical skills. Ensure your team understands how fatigue, distractions, cognitive overload, and poor communication can contribute to errors.

Use real-life scenarios, case studies, and hands-on simulations to reinforce learning. Regularly refresh safety training and tailor it to job roles to keep the knowledge relevant and applicable.

4. Promote Safety Culture and Psychosocial Measures

A positive safety culture starts with trust. Encourage open communication where employees feel safe to report hazards, mistakes, or concerns without fear of blame. Foster psychological safety so that when people can speak up, problems are addressed early.

Also, focus on Psychosocial Safety Climate (PSC) by showing visible support from leadership for mental health, workload balance, and respectful interactions. This reduces stress and boosts engagement.

5. Use Technology and Conduct Monitoring

Use technology to support safety, not replace people. Wearable devices, connected-worker platforms, and fatigue-monitoring tools can provide real-time insights into physical strain, posture, or high-risk movements.

These tools help you track trends, intervene early, and adjust work conditions based on actual data. Ensure the technology is user-friendly and easily integrated into daily routines.

6. Make Continuous Improvement

Human factors integration is not a one-time project; it is an ongoing process. Build a feedback loop into your safety system. Track near-misses, gather frontline feedback, and review incident reports for human-related causes.

Update procedures, redesign tasks, or improve training based on what you learn. This ongoing cycle keeps your system responsive and relevant as conditions and work demands change.

Partner with Safe T Professionals to Strengthen Your Workplace Safety

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s safety protocols and ensure compliance with industry standards. Whether you’re looking to fill safety-specific roles or need expert consultation to mitigate workplace hazards, we’re here to help.

Connect with us today!