In construction, a single overlooked hazard can bring an entire project and a life to a standstill.

From working high on scaffolding to lifting heavy steel beams, every part of a construction project has potential dangers. Falls, electrocution, struck‑by accidents, and caught‑in‑between incidents are among the most common causes of serious injuries and deaths in the industry. Even smaller hazards, like poor housekeeping or faulty equipment, can lead to costly delays, medical bills, and lost work time.

The means of reducing these risks is strong hazard prevention and control. This means spotting dangers early, putting effective safety measures in place, and making sure they are followed consistently.

On a busy site, where different trades work side‑by‑side and conditions change every day, this requires a planned, ongoing approach.

That’s where hazard control personnel come in. They are the trained professionals who inspect the site, assess risks, choose the safest control methods, and work with the crew to ensure everyone goes home safe at the end of the day.

In this blog, we’ll explore how hazard control personnel help keep construction sites safe, the process they follow, the challenges they face, and how their work benefits both workers and the project as a whole.

Why Hazard Prevention and Control Matters for Safe and Efficient Projects

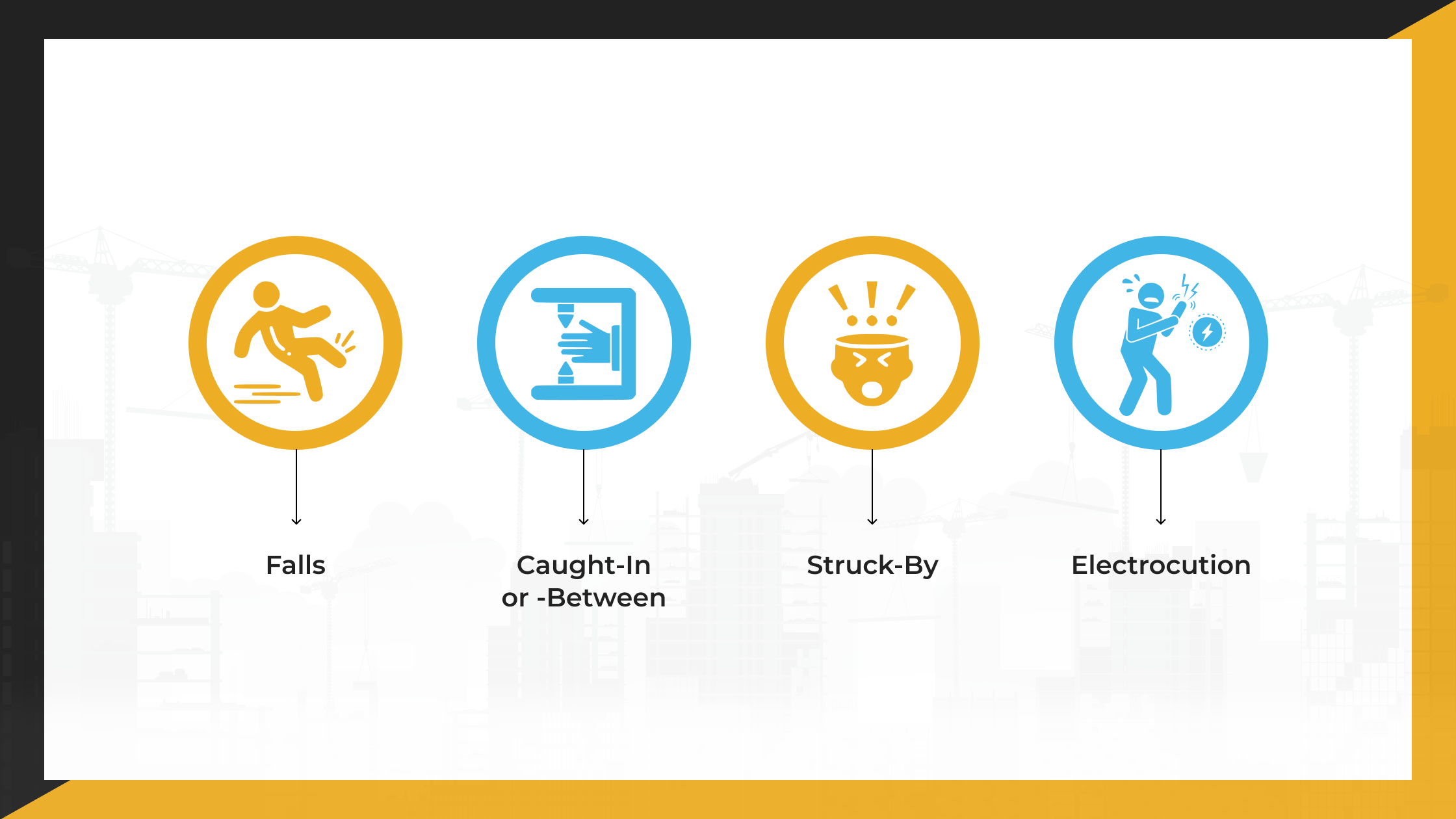

Construction is one of the most hazardous industries. According to OSHA, a large number of workplace deaths and serious injuries in construction come from four main hazards:

- Falls from heights

- Being struck by objects

- Caught-In or Between

- Electrical shocks

Workers may also face exposure to harmful substances like silica dust, which can cause long-term health problems.

OSHA’s Recommended Practices for Safety and Health Programs in Construction promote a “find and fix” approach. This means identifying hazards as early as possible and taking steps to remove or reduce them before they cause harm. Hazard Prevention and Control is one of the seven primary elements in this system, and it focuses on putting effective safety measures in place once a hazard has been identified.

An effective hazard prevention program benefits both the company and its employees by reducing the number of injuries and illnesses on the job site, keeping work on schedule by avoiding disruptions from accidents, lowering costs related to workers’ compensation claims and creating a safer environment that encourages workers to stay with the company

By making hazard prevention and control a consistent priority, construction employers can meet legal requirements, protect their workforce, and run projects more smoothly.

Hazard Control Personnel: Roles, Skills, and Workplace Placement

Hazard control personnel may be designated under different job titles depending on the organisation and industry. Common examples include:

| Title | Description |

| Safety Officer | Oversees daily workplace safety activities and ensures compliance with safety regulations. |

| Safety Specialist | Focuses on specific safety areas such as process safety, electrical safety, or chemical safety. |

| SHE Technician (Safety, Health, and Environment) | Provides technical support in hazard identification, safety inspections, and environmental monitoring.

|

| HSE Coordinator/Advisor | Coordinates safety programmes and liaises between management and workers. |

| Risk Control Officer | Concentrates on risk assessment and control plan implementation. |

Required Education, Competencies, and Certifications

To perform effectively, hazard control personnel need:

- Educational Qualification – A diploma or degree in occupational health and safety, engineering, environmental science, or a related field.

- HIRA Proficiency – Ability to conduct Hazard Identification and Risk Assessment accurately.

- Incident Investigation Skills – Understanding root cause analysis and corrective action planning.

- First Aid and Emergency Response – Capability to respond quickly and effectively to workplace incidents.

- Regulatory Knowledge – Familiarity with local and international safety regulations and standards.

Certifications

The required certifications for hazard control personnel vary by region and industry. Common examples include the NEBOSH International General Certificate (IGC), OSHA training certifications, ISO 45001 Lead Auditor Certification, and First Aid/CPR certification. These credentials ensure that personnel are equipped with both technical knowledge and practical skills to manage workplace safety effectively.

Organisational Placement

Hazard control personnel usually report to the Safety Manager, HSE Manager, Plant Manager, or directly to Operations leadership, depending on company size. They work across multiple departments, such as operations, maintenance, HR, and procurement, to integrate safety into all activities.

On a practical level, they collaborate with supervisors to enforce safety rules, coordinate with contractors to ensure compliance, and liaise with regulatory inspectors or auditors during safety assessments.

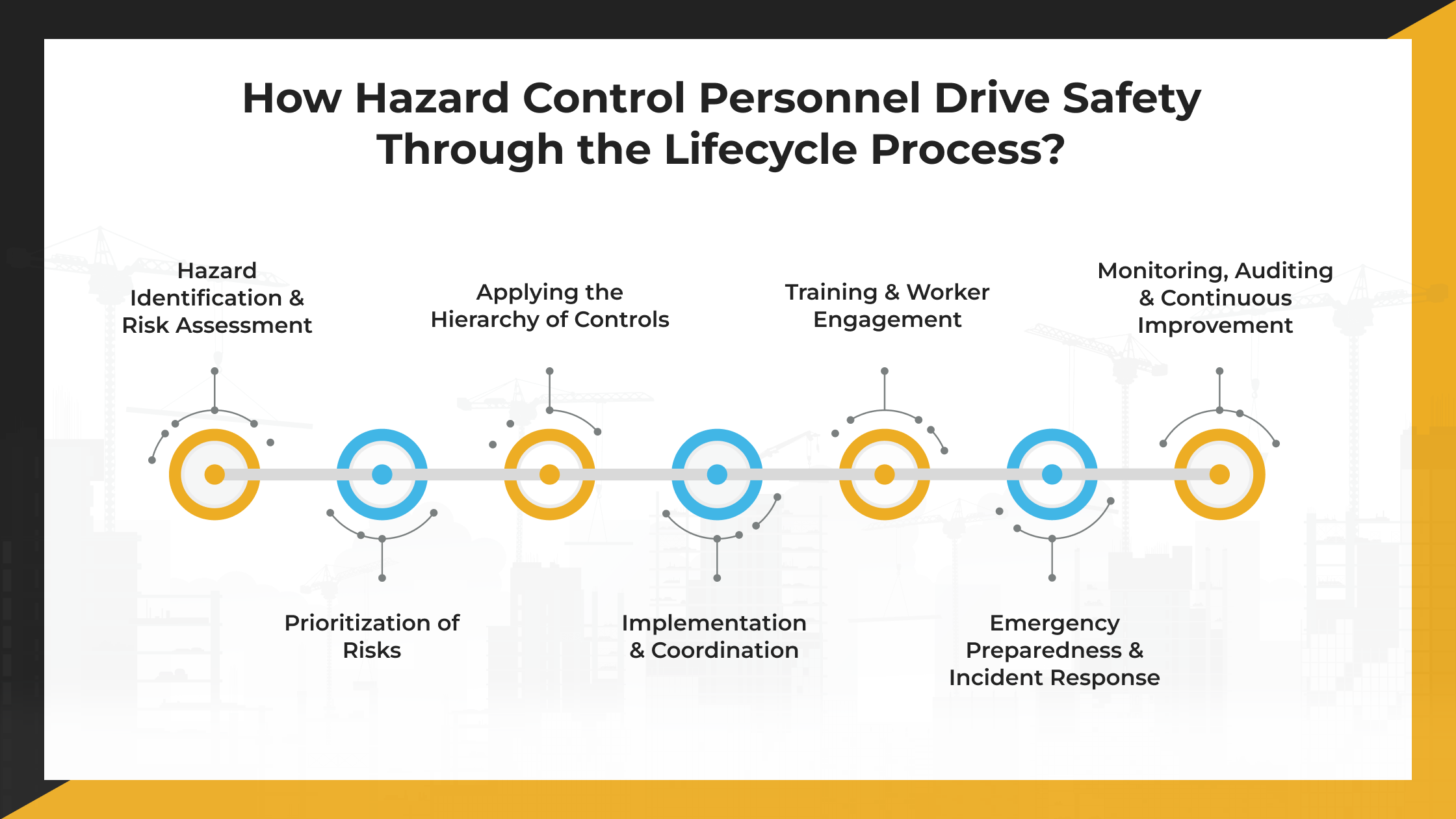

How Hazard Control Personnel Drive Safety Through the Lifecycle Process?

Here is how hazard control personnel manage each stage of the safety lifecycle to identify risks, apply effective controls, and maintain a safe work environment.

1. Hazard Identification & Risk Assessment

Hazard identification is the first step in preventing workplace incidents. This involves systematically checking for anything that could cause harm. Common methods include:

- Walkthrough Inspections – Regularly moving through work areas to spot unsafe conditions, such as exposed wiring or poor ventilation.

- Permits-to-Work Reviews – Ensuring hazardous tasks like hot work or confined space entry are authorised and controlled.

- Task Analyses – Breaking down each job step to identify where hazards may occur.

Once hazards are identified, a risk assessment is carried out to determine how likely an incident is and how severe its impact could be.

Many organisations use the HIRARC method (Hazard Identification – Risk Assessment – Risk Control). For example, in a manufacturing plant, operating a cutting machine without guards would be rated as a high-severity, high-likelihood hazard.

2. Prioritization of Risks

Not all hazards have the same potential for harm. A risk matrix is often used to prioritise them based on severity and likelihood.

High-consequence hazards, such as working at height without fall protection, are addressed first because they can cause serious injury or death. Lower-consequence hazards, like minor ergonomic issues, are scheduled for later action unless they pose a growing risk.

This prioritisation ensures that resources and time are focused on the most critical safety issues first.

3. Applying the Hierarchy of Controls

The Hierarchy of Controls provides a structured way to address hazards, starting with the most effective measures:

| Hierarchy of Controls | Description | Example |

| Elimination | Remove the hazard entirely | Replace a chemical process with a safer method so the chemical is no longer used. |

| Substitution | Replace a hazardous substance or process with a less dangerous one. | Use water-based paint instead of solvent-based paint. |

| Engineering Controls | Isolate people from the hazard | Install machine guards or ventilation systems. |

| Administrative Controls | Change the way people work. | Rotate shifts to limit exposure to noise. |

| PPE (Personal Protective Equipment) | Use safety gear like helmets, gloves, or respirators when other controls cannot fully remove the risk. | Wearing a hard hat and steel‑toe boots while working in areas with falling object hazards. |

This order ensures that hazard reduction focuses first on permanent solutions before relying on worker behaviour or protective equipment.

4. Implementation & Coordination

A hazard control plan is created to implement the chosen controls. The plan should clearly state the specific control measures to be used, who is responsible for each action, deadlines for completion, and the budget or resources needed.

For example, suppose noise levels in a workshop are above legal limits. In that case, the plan might include installing soundproof panels, assigning a project leader, and setting a two‑month deadline for completion. Coordination between safety personnel, supervisors, and maintenance teams is key to ensuring timely action.

5. Training & Worker Engagement

Hazard controls are only adequate if workers understand and follow them. Training should cover:

- Toolbox Talks – Short daily or weekly safety discussions before starting work.

- Induction Training – Safety orientation for new employees before they begin work.

- Ongoing Awareness – Addressing safety concerns during inspections and responding to worker feedback.

For example, before introducing a new chemical cleaning agent, workers should be trained on safe handling, storage, and emergency spill response.

6. Emergency Preparedness & Incident Response

Even with strong prevention measures, emergencies can still occur. Hazard control personnel prepare by developing written procedures for situations such as fires, chemical spills, or medical incidents. They conduct drills to ensure everyone knows how to evacuate or contain a spill. If an incident happens, they carry out a root cause analysis to prevent it from happening again.

For instance, if a forklift accident happens, an investigation might reveal that the driver’s view was blocked by stacked pallets, leading to a change in storage layout.

7. Monitoring, Auditing & Continuous Improvement

Regular checks ensure that controls remain effective over time. This includes:

- Audits – Formal reviews of safety procedures and compliance.

- Inspections – Routine checks of equipment and work areas.

- Performance Tracking – Monitoring indicators such as the number of near misses or safety observations.

- Trend Analysis – Looking at data over time to identify recurring issues.

For instance, if inspection data shows repeated reports of frayed electrical cords, the organisation may need to change its equipment maintenance policy.

Challenges in Hazard Control and How to Overcome Them

Here is a breakdown of a few of the challenges faced by these personal and effective ways to tackle them:

Budget and Resource Constraints

Many organisations have limited funds and manpower for hazard control activities. This often means not all hazards can be addressed at once. Safety improvements like engineering controls or specialised equipment can be costly, making it challenging to implement all measures at once.

Prioritise high‑risk hazards first. Use a risk matrix to decide which issues must be resolved immediately and which can be scheduled for later. For example, fixing a faulty gas detection system should take precedence over repainting safety signs. Cost‑effective solutions, such as administrative controls or procedural changes, can be used temporarily while waiting for larger investments.

Resistance to Change

Workers and supervisors may be reluctant to alter familiar routines, even if current practices carry risks. Long‑standing habits can lead to complacency, making people less likely to follow new safety procedures.

Involve employees in decision‑making about hazard controls so they understand the reasons behind changes. Peer‑to‑peer safety advocacy can be effective, as workers often respond better to colleagues than to formal directives. For example, appointing a respected team member as a safety champion can encourage others to adopt safer methods.

Hazard Complexity

Some hazards are not straightforward to identify or control, such as ergonomic strain, psychosocial stress, or highly specialised process risks. These hazards may require different expertise, long‑term monitoring, or changes in workplace culture.

Break down complex hazards into smaller, manageable components. For instance, in ergonomic risk mitigation, address one workstation or process at a time rather than attempting a site‑wide overhaul. Consult with specialists where needed to ensure accurate assessment and control.

Emerging Trends & The Future of Hazard Control Roles

Here is a list of emerging trends that can help hazard control personnel work more efficiently, prevent incidents more effectively, and adapt to the changing demands of modern worksites.

Digital Transformation

Technology is transforming how hazard control personnel monitor and manage workplace safety. Health, Safety, and Environment (HSE) software centralises incident reporting, inspections, and corrective action tracking, making data easier to access and analyse. Mobile applications allow workers to instantly report hazards with photos and location details, ensuring faster response times.

Internet of Things (IoT) sensors continuously monitor conditions such as gas levels, temperature, and equipment vibration, providing real‑time alerts when thresholds are exceeded. Real‑time dashboards then give safety teams an overview of ongoing risks.

For example, in a chemical plant, IoT‑linked gas detectors can notify staff immediately if harmful gases are detected, prompting a swift evacuation.

Prevention Through Design (PtD)

PtD focuses on eliminating or reducing hazards at the design stage of equipment, facilities, and processes. By involving hazard control personnel early in planning, risks can be addressed before operations begin. This may include designing machinery with built‑in safety guards, creating layouts that separate pedestrian and vehicle routes, or adding fall‑protection anchor points during construction.

For example, a warehouse designed with integrated overhead safety rails avoids the need for costly retrofits later and improves worker safety from day one.

Psychosocial Safety

Modern safety management extends beyond traditional physical hazards to include psychosocial and human‑related risks. Psychosocial safety addresses mental health factors such as workplace stress, high workloads, and harassment.

Human factors engineering focuses on designing work systems that match human abilities and limitations. Behavioural safety programmes reinforce safe practices through observation, feedback, and positive reinforcement.

For example, introducing flexible work shifts in a factory can reduce fatigue, improve focus, and lower the risk of accidents caused by human error.

Integration with Sustainability and Environmental Systems

This integration allows safety measures to align with environmental goals, reduces duplication of resources, and ensures compliance with both safety and environmental regulations.

For example, installing energy‑efficient ventilation systems not only improves indoor air quality for workers but also reduces a facility’s energy consumption and carbon footprint.

Build a Safer Workplace with Expert Safety Staffing Solutions

At Safe T Professionals, we are dedicated to elevating safety standards through our expert consulting and staffing services. By proactively addressing and preventing safety issues and equipping your workforce with the necessary knowledge and tools, we help create a safer work environment.

Partner with Safe T Professionals to enhance your company’s HSE protocols, ensure compliance with industry regulations, and mitigate workplace hazards. Whether you are looking to fill safety-specific roles or need expert consultation to reduce workplace hazards, we are here to help.

Connect with us today!